XCVIII

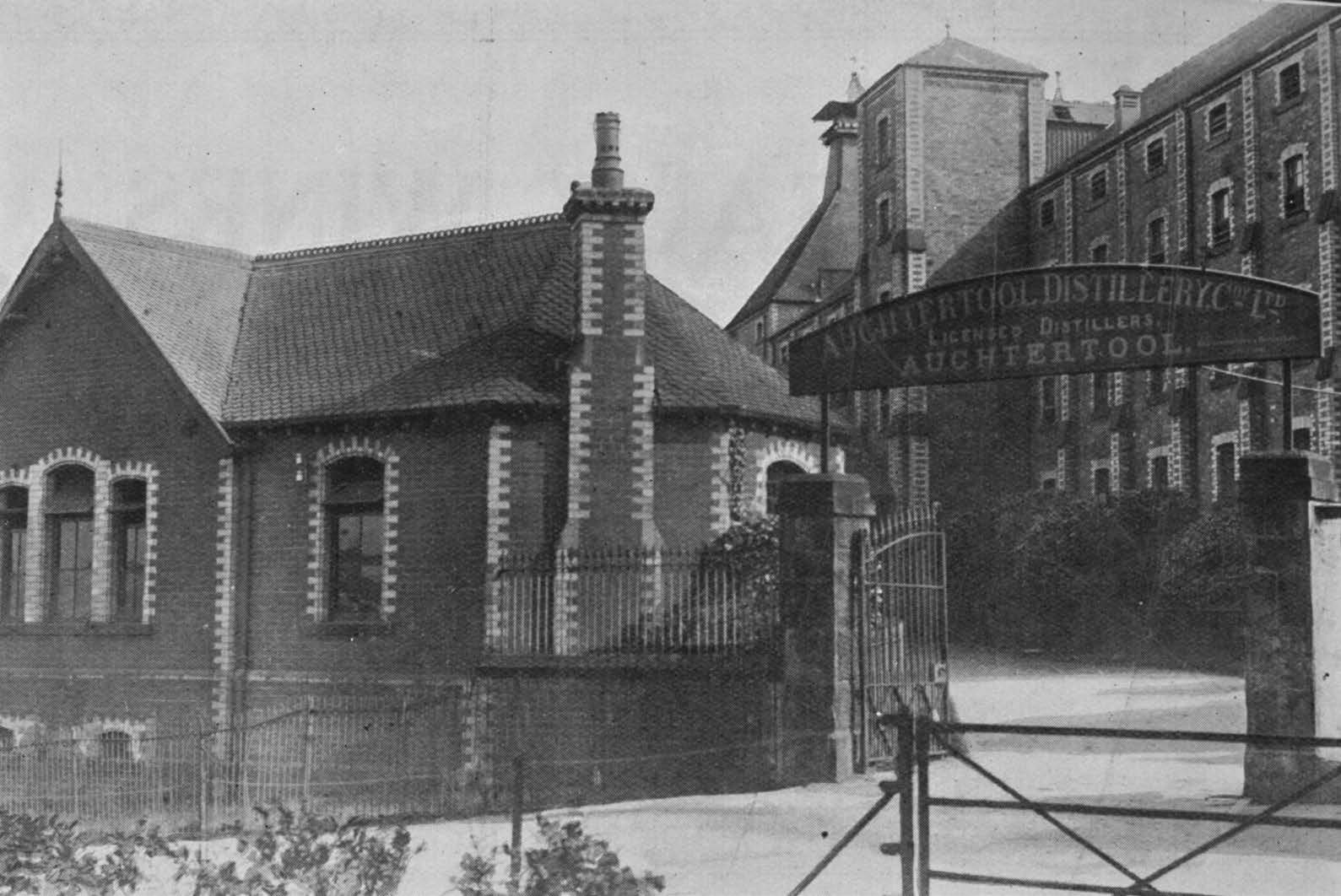

Auchtertool Distillery, Kirkcaldy, Fifeshire

January 14th, 1926

The Auchtertool district, which lies up on the hills about four miles from the busy industrial town of Kirkcaldy, has in former times been the scene of stirring incidents which have helped to make Scottish history. Away to the right on the road up from Kirkcaldy, and rather more than half-a-mile from the hamlet, there is a large wood, on the outskirts of which was fought the last duel in Scotland. The opponents were Alexander Stewart on the one side, and Boswell, of Balmuto House, on the other; and although the conflict took place more than a hundred years ago, the memory of the struggle vividly awakens the imagination to this day.

From the distillery, which stands many hundred feet above the sea level, several landmarks of Scottish history may be distinguished on a clear day. Not the least interesting is Kirkcaldy Bay. At the east end of the harbour stand the ruins of the Castle of Ravenscraig. In its better days, about 1470, this property was conferred by James III on the Earl of St. Clair of Orkney, on the latter’s resigning the title.

Kirkcaldy is a royal borough, which gives it distinction among Scottish towns. But, what is more important, it forms a busy hive of industry when times are good, as there are prosperous linoleum and other factories which find a large amount of steady employment.

In the annals of our national beverages Auchtertool has played an important part, for the distillery, which is a conspicuous landmark for many miles round, was built for a brewery as far back as 1650, and so it was conducted for a number of years. It must have had a fine career as a brewery, for a hundred years after it was started its excellent Beer was noted throughout Fifeshire. What its fortunes were between the late seventeenth century and 1845 can only be a matter of conjecture. But in this year an enterprising distiller, appreciating the resources of the district, took over the premises, and produced an excellent Whisky. This was not a matter for wonder, having regard to the purity of the water and the superior character of the barley grown in the district.

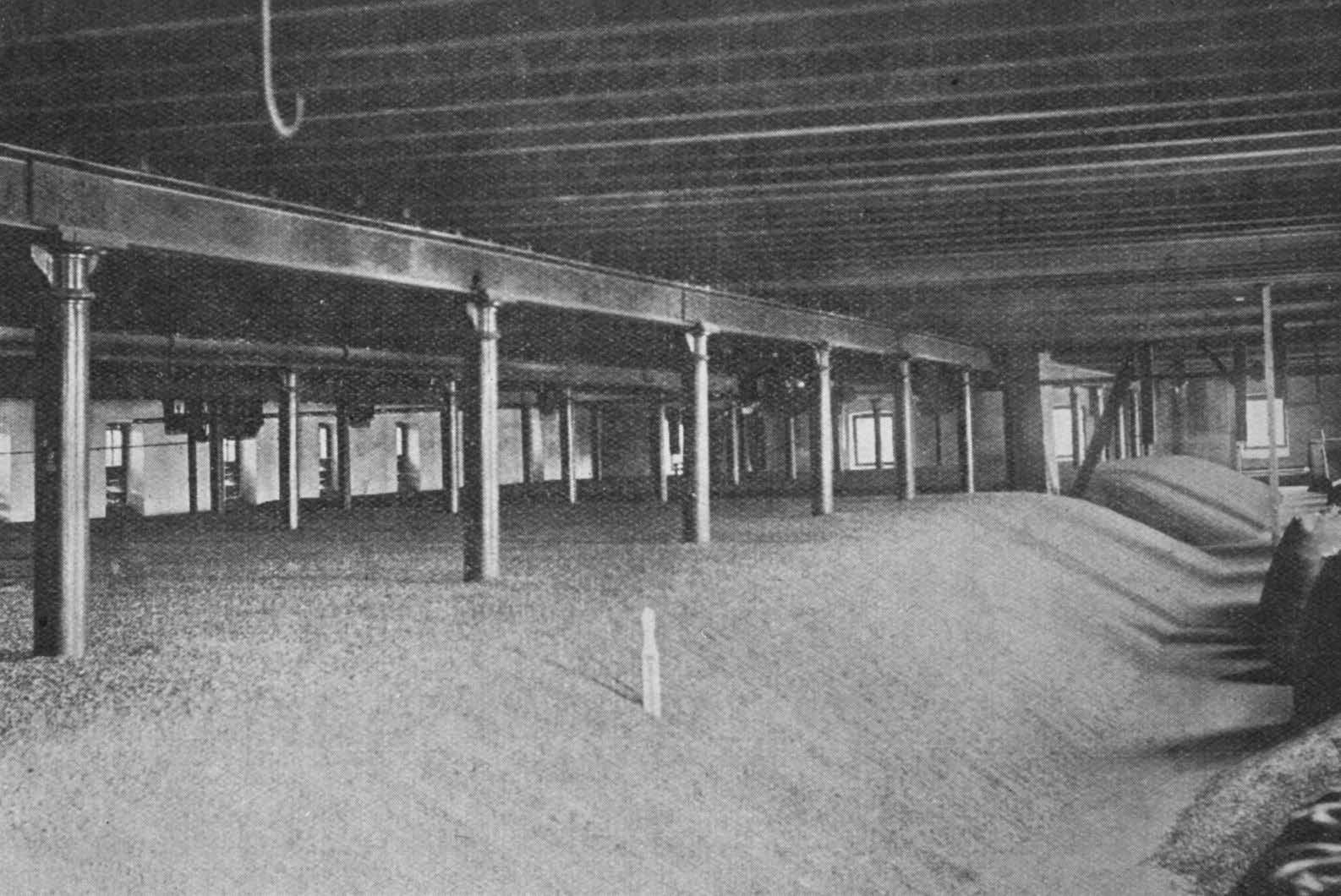

Within the eighty years of the Auchtertool distillery’s career there have been many improvements in the buildings and in the plant. Some account of the present capacity will be read with interest. The malt barns, consisting of four storeys, 200 ft. long and 60 ft. wide, is of very handsome appearance, and is considered the finest in the country. The barley is conveyed to the top floors by an elevator, passed through a cleaner, and thence to any part of the loft by carrying bands. The barns consist of two barley lofts and two malting floors with two cast-iron steeps, each of 100 quarters capacity. The barley is dropped from the steeps into baskets hung on rails and conveyed to any part of the floor. The kilns, 30 ft. by 30 ft., floored with Herman wire, are “double deckers,” and are loaded by an elevator, and the finished malt discharged by a screw conveyor to the malt binns of 1,600 quarters capacity. The malt is automatically weighed and cleaned, and then ground by a “Porteous” mill, after which it is conveyed to the grist hoppers.

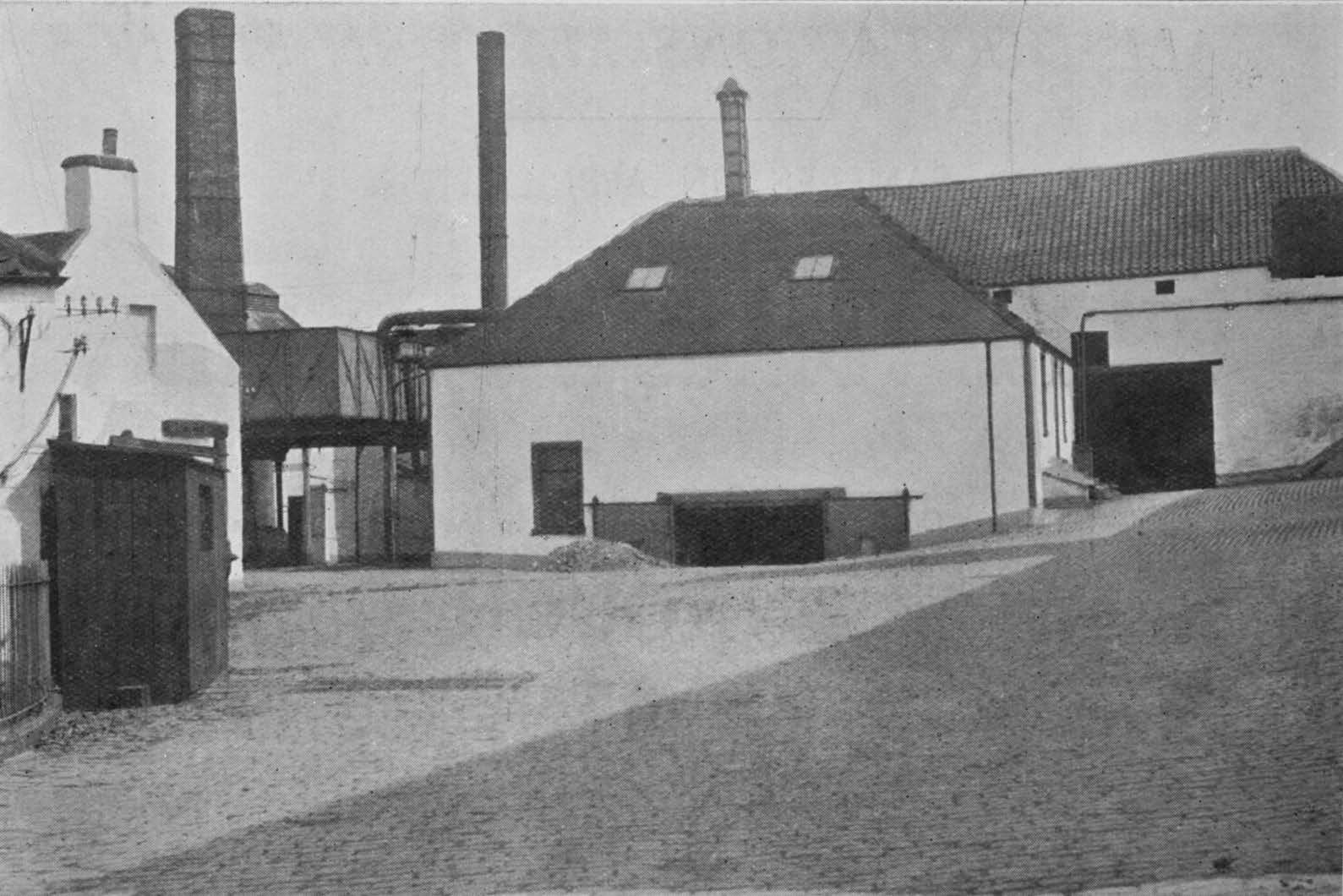

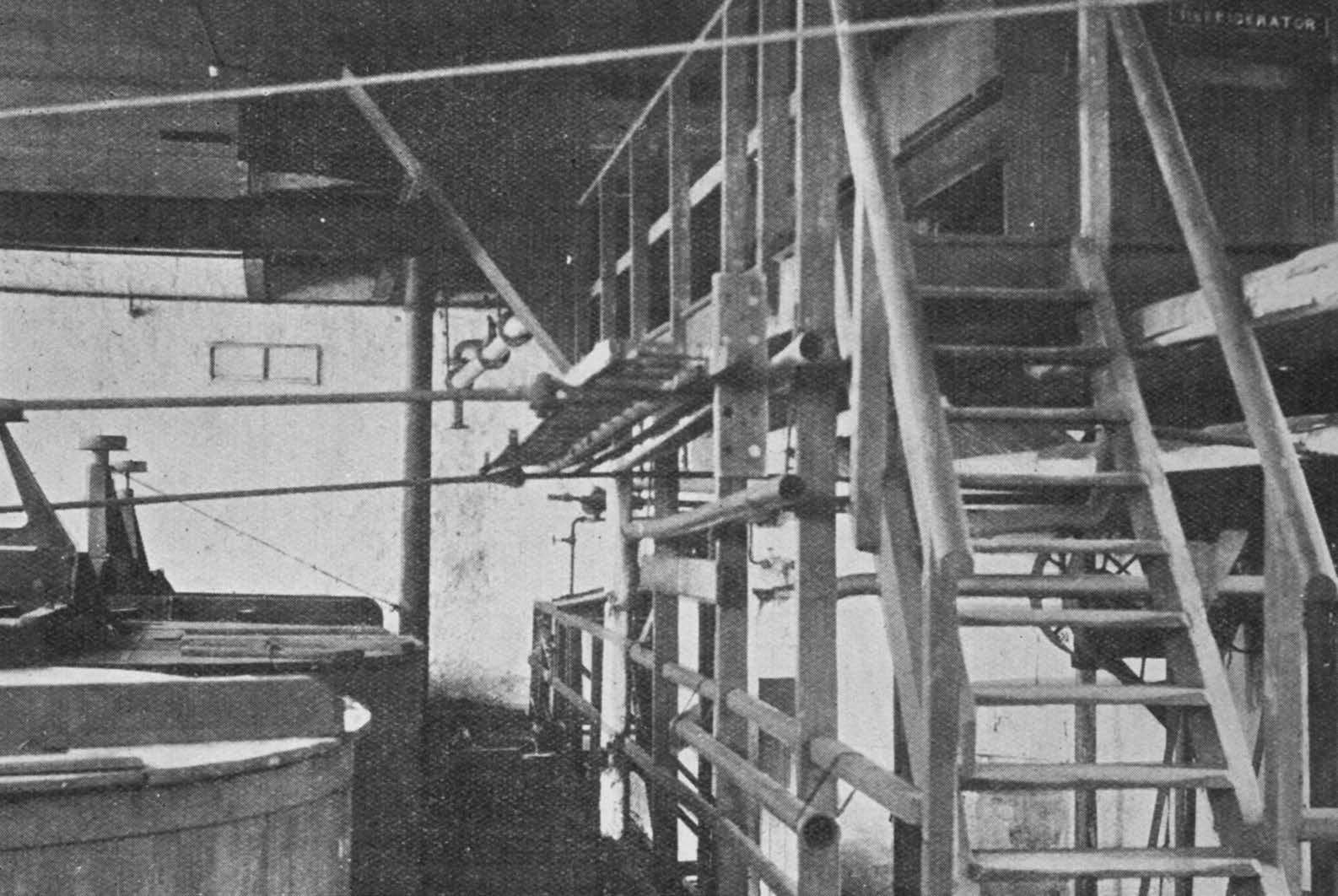

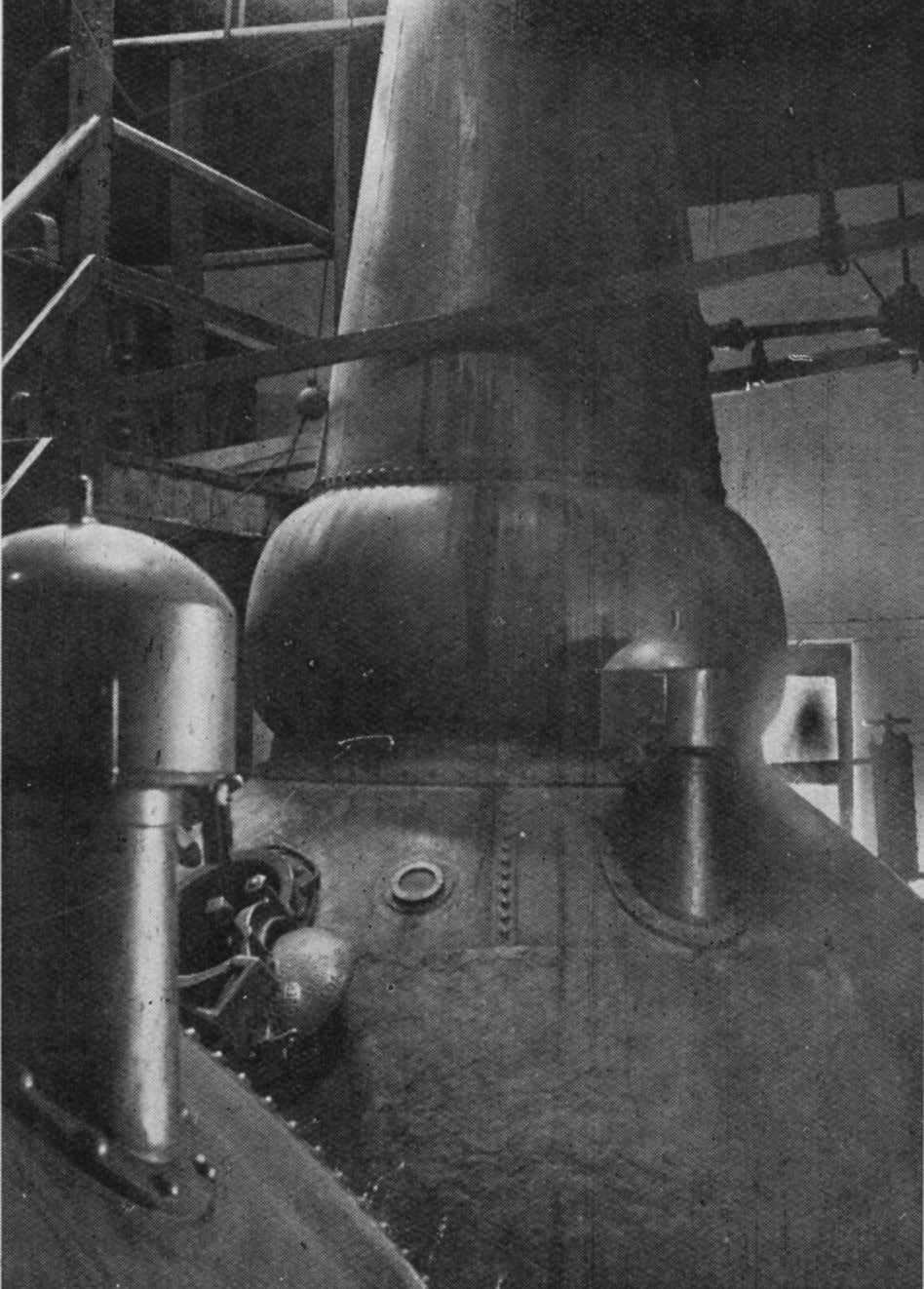

The mash-house contains two heating tanks and a mash tun 16 ft. in diameter with a steel masher and sparger. 1,600 bushels are mashed weekly, producing over 4,000 gallons of Spirit. The draff is pumped from the mash tun to a tank overhead, where it is all loaded into local farmers’ carts. The worts are pumped from the underback to the worts receiver, passed through the refrigerator, thence into the wash-backs in the tun room. There are six wash-backs, each of 10,000 gallons capacity, with the usual switching gear. The still-house is a large building containing two stills, wash charger, low Wines and Spirit receivers. The wash-still is of 4,000 gallons, and the Spirit still of 3,000 gallons capacity. Alongside the still-house is a large “Lancashire” boiler and a “Blair Campbell and McLean” draff drier, which dries any surplus draff in the summer. There are three large and commodious warehouses containing 9,000 casks, but capable of holding 14,000 casks or about 1,000,000 gallons. The annual make is from 120,000 to 125,000 gallons.

The effluent is pumped to the hills, about a mile from the distillery, and sprayed all over the fields by means of pipes. The distillery is lit by electricity, made by a small power plant installed a few years ago. The water comes from the peat moss at Moss Morne, about three miles distant, into a reservoir, thence through pipes to the distillery.

Among the extensions of plant on the company’s accession to the business were malt hoppers, draff tank, draff drier, and a 7 ft. Lancashire boiler. The barley used is mostly grown in Fifeshire.

After being carried on by Mr. Bartholomew from the date of its commencement, it passed into the hands of Mr. Thomas Sanderson, of Leith, and afterwards was transferred to the Auchtertool Distillery Co., Ltd. Mr. M. Young, the manager, who for 25 years was at Bo’Ness Distillery, came to Auchtertool with the company.

Images © The British Library Board