LXXXI

Benrinnes Distillery, Near Aberlour

May 14th, 1925

Benrinnes distillery lies in a lonely valley a few miles above Aberlour. The site is partly enclosed by belts of fir trees, and most of the neighbourhood is bleak and barren, but the distillery was originally placed there mainly on account of the excellent water supply from the mountainous crags of Benrinnes, which rise to a great height behind the premises.

Established in the year 1835, Benrinnes has been rebuilt several times, but the distillery remains old-fashioned in many respects, although the Whisky produced is well worthy of the Speyside district. In common with most of the old distilleries, Benrinnes is handicapped by lack of railway facilities. All supplies have to be carted away from Aberlour station, three miles distant – an awkward process during the severe winters which generally affect this wild locality. Motor waggons are, therefore, employed for carrying barley, coal, and Whisky to and from the station.

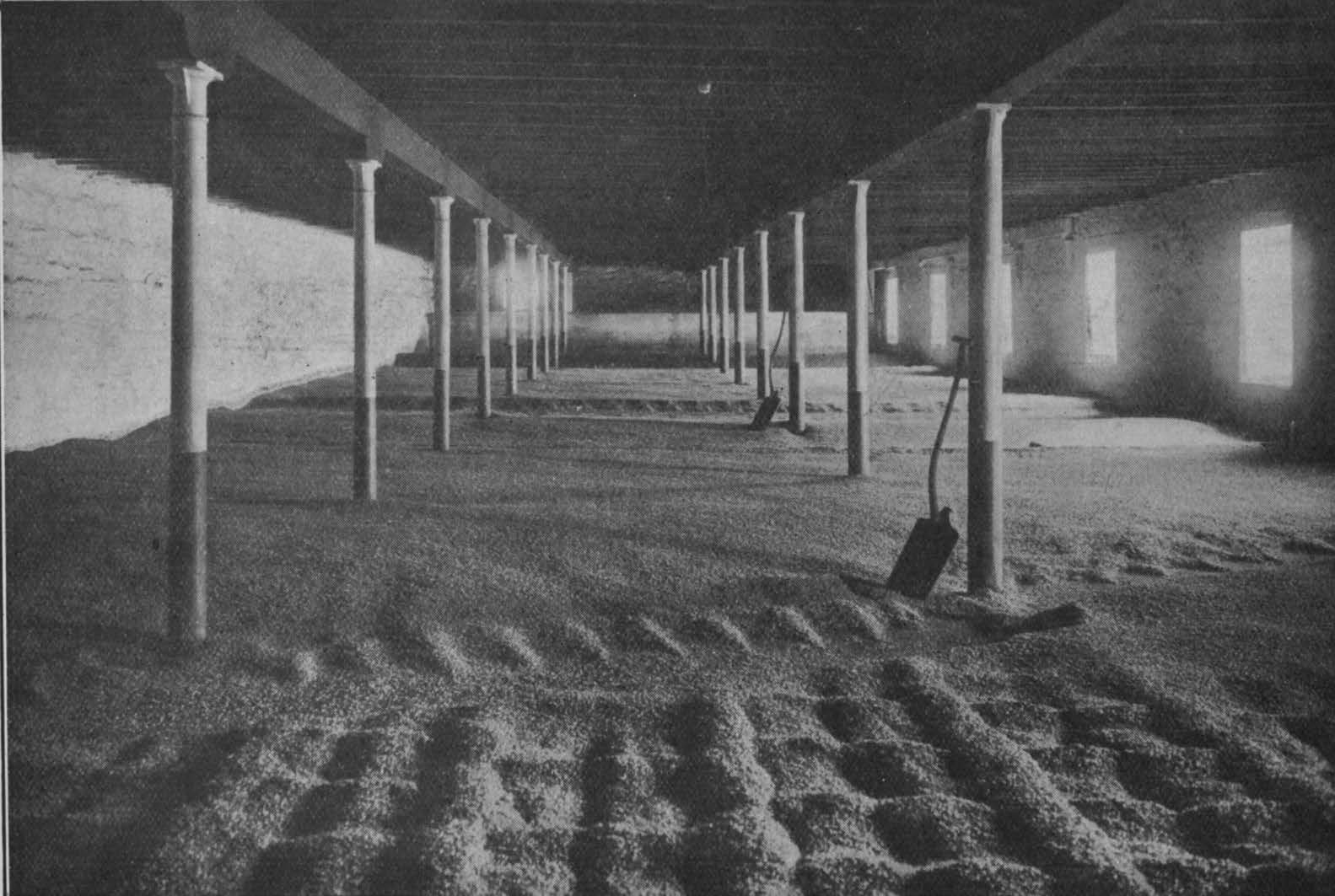

Barley is hoisted to a capacious loft, and afterwards dropped through four hatches in the floor to two steeps holding respectively sixty and thirty quarters at a time. There are three extensive malting floors on the lower storeys of the building, and from these the malt is elevated to a wire-floored kiln and dried by peat and coke. Peat is predominant in the mixture. Conveyors are used to remove the dried malt from the kiln to six malt hoppers of nine hundred quarters’ total capacity. Before passing to the two-roller mill for grinding, the malt is measured by a two-bushel automatic weigher, and from the mill the grist is elevated direct to four hoppers above the mash-tun in which 1,800 bushels can be mashed every week.

The tun-room holds three large and six small wash-backs with switchers. The driving power is supplied by a water-wheel in the heart of the building, and a horizontal steam engine.

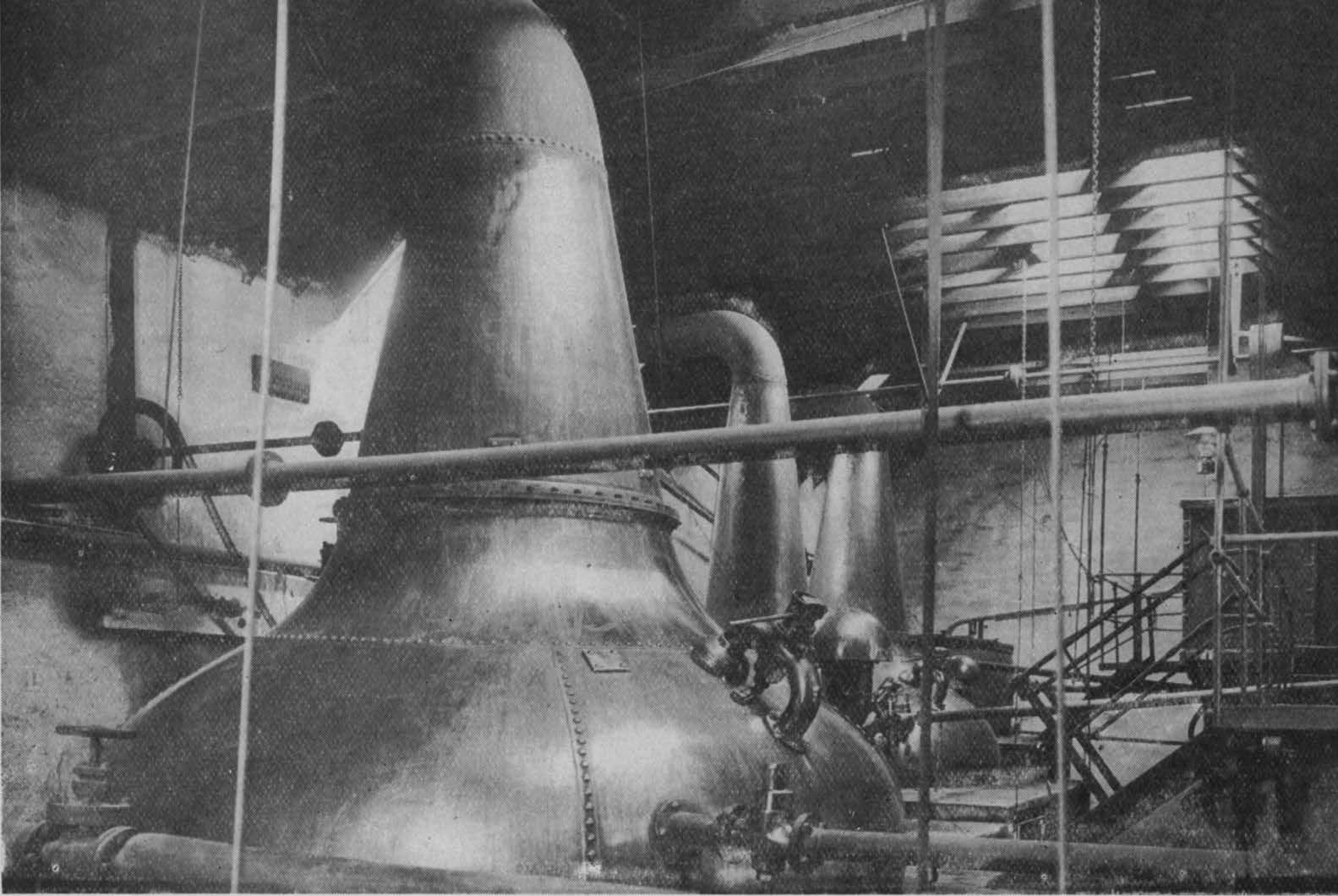

In the still-house are a large copper heated by furnace and a steam-heated tank for maintaining a constant supply of hot water. Nearby are three stills. The wash-still has a charging capacity of four thousand gallons, and the residue of burnt-ale is pumped to a tank outside the premises and carted on to arable land on the farm attached to the distillery. Spent lees from the Spirit stills and steeping water are run by gravitation into two settling tanks, and later purified in filter-beds of gravel and cinders.

Adjacent to the still-house is the usual type of receiver-room with pumps for Spirits and feints, and opposite the malting and distilling buildings are a number of warehouses with room for over ten thousand casks of Whisky.

The Spirit produced at Benrinnes is known as “Benrinnes-Glenlivet” Highland Malt Whisky.

Images © The British Library Board