VI

Craigellachie Distillery, Banffshire

February 14th, 1923

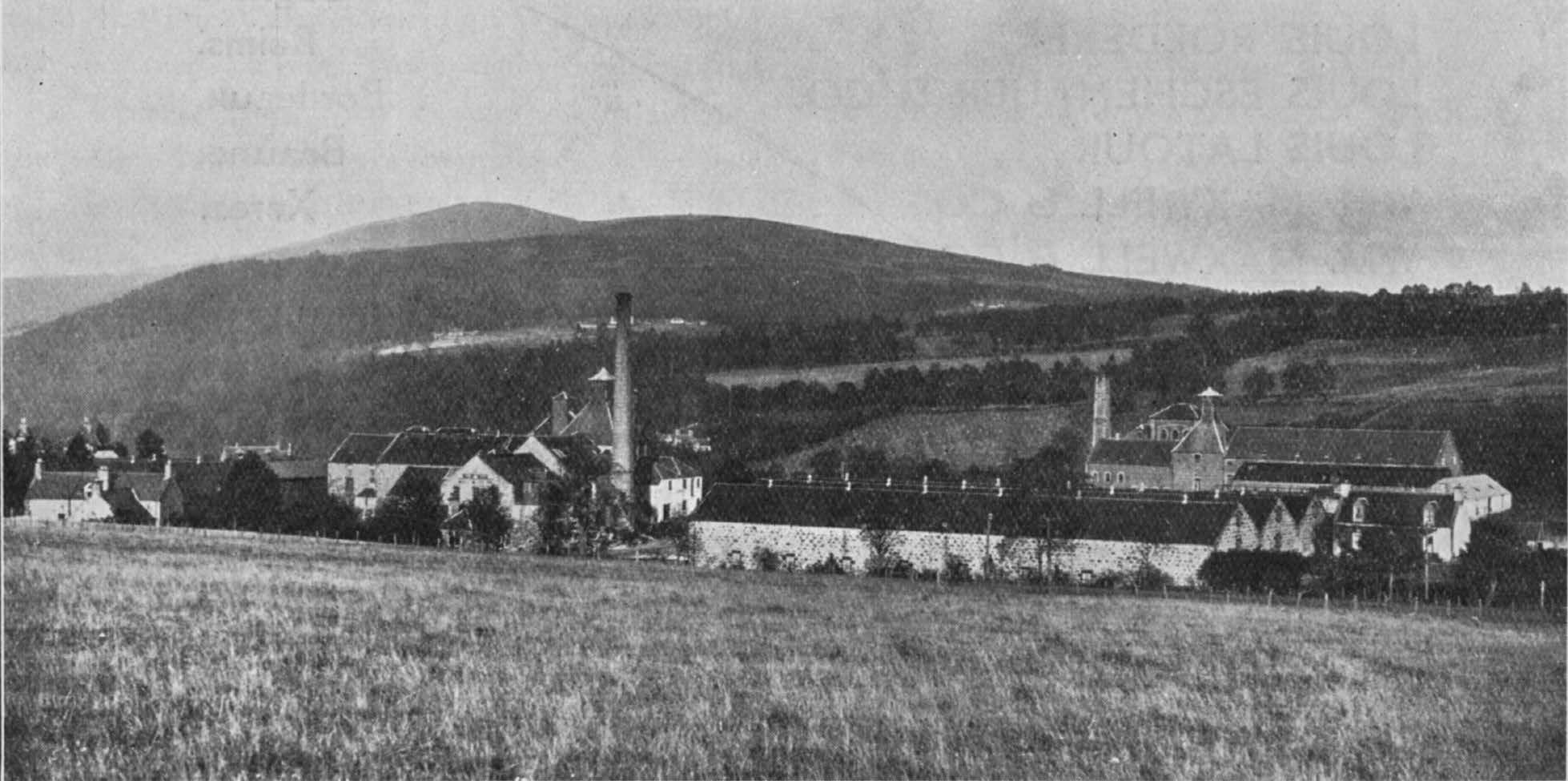

Beautifully situated on the spur of a hill above the pretty little Highland village of Craigellachie, within view of the towering mountain of Ben Rinnes, the wooded Glenlivet Hills, and the peaceful silver windings of the River Spey, is Craigellachie Distillery. The district has long been celebrated as one of the most picturesque parts of Scotland, and besides being a happy hunting-ground of tourists and fishing enthusiasts, it produces a Malt Whisky well worthy of its natural surroundings.

Erected some thirty years ago, Craigellachie Distillery is one of the group owned by Messrs. Mackie and Co., Distillers, Ltd., whose famous “White Horse” Whisky is largely composed of the Spirit produced here. The outstanding feature, perhaps, is the scientific purification plant installed a few years ago by the present owners, but in every respect the distillery can be considered to be among the most efficient and up- to-date in Scotland.

Passing up the steep road to the premises one notices a number of trim little cottages occupied by the employees, with carefully-tended gardens that make the village a place of enchantment in the summer months. Every year the directors of the firm inspect these gardens, and offer prizes for those that have been kept in the best condition.

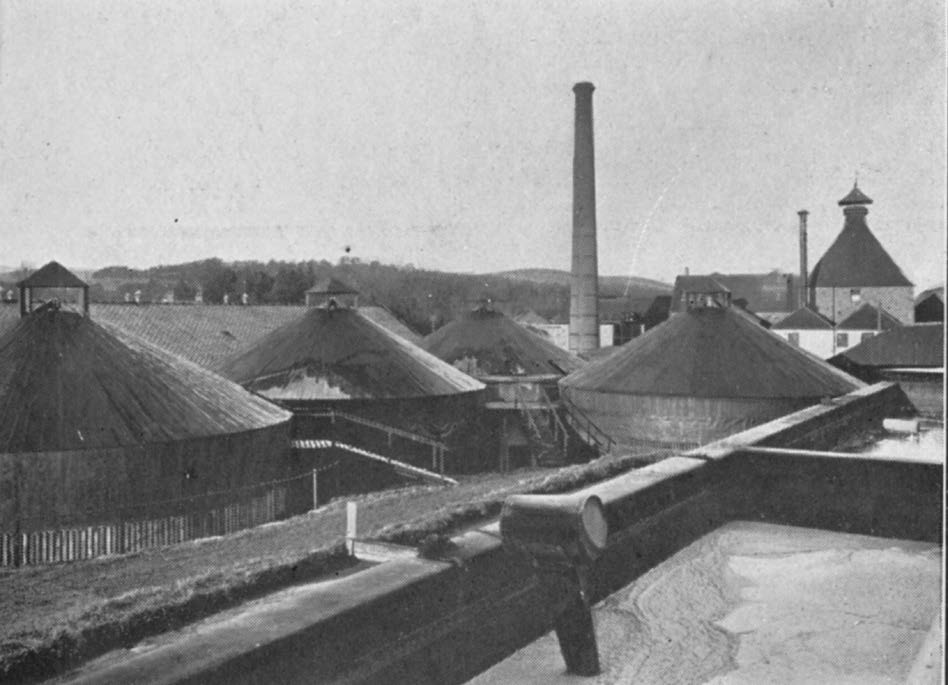

The distillery stands in a large open space, and the buildings are conveniently planned for smooth-running production. Malting is carried on in two separate sections of the premises, comprising two barley lofts, six steeps, four malting floors, and two kilns. The barley used is mostly Scotch, with a small percentage of foreign. At intervals of ten yards in the loft floors are small holes through which the grain is dropped on to a band conveyor, and so distributed to any part of the malting floors beneath. The steeps also may be loaded by means of the conveyor, and malt is taken to the kilns by elevator. Each with a capacity of 30 quarters, the kilns are fitted with King’s patent turning machines, which give very satisfactory results, and the furnaces, burning equal quantities of peat and coke, have patent ventilators of the latest pattern.

In the mash-house, adjoining the maltings, the first thing that strikes the eye is the mash- tun entirely covered in by steel shutters. This contrivance enables the striking heat to be supplied at a much lower temperature and still give the normal setting heat of the mash, since the heat is conserved by the steel covering over the tun. High temperature mashing produces bad worts, so the advantage is obvious. The shutters are easily removed for reception of the malt and water from the patent mashing machine above the tun. Seven mashes are carried out each week. Draff is pumped out of the tun by a special pump, and carted away every day by farmers for feeding purposes. There is also a draff-drying machine. The still-house at Craigellachie contains an exceptionally large boiler, 8ft. 6in. high and 31ft. long. A hot-water collecting tank and two bulky coppers are grouped on a platform opposite the stills, and any form of steam wastage is avoided by an ingenious system of heating. Exhaust from the engines passes through a heating tank before reaching the coppers, which are fitted with patent steam-heating tubes. After it has heated the water in the coppers a further use is found for the steam which originally came from the exhaust. On leaving the coppers it condenses, and goes on to the boilers, so that there is no loophole for waste, and a consequent saving of coal. The stills are among the largest in Speyside; the wash still with a capacity of 6,500 gallons, and the low-wines still with accommodation for 5,900 gallons. Power is supplied by a fine horizontal engine of 30-40 h.p., and subsidiary plant for driving the switchers in the wash-backs, and other purposes. Coal for the boilers is carted actually into the building, with a view to saving manual labour.

The tun-room is a long spacious apartment with six wash-backs, one being filled twice to cope with the seven weekly mashes. Fermentation at this distillery is unusually strong, and proof of this was seen in the form of substantial bars of iron which had been placed on the top of one wash-back, in order to restrain the lively “wash” from spouting up towards the roof of the building. A separate room is set aside for the Spirit safes, receivers, and other appliances of this kind.

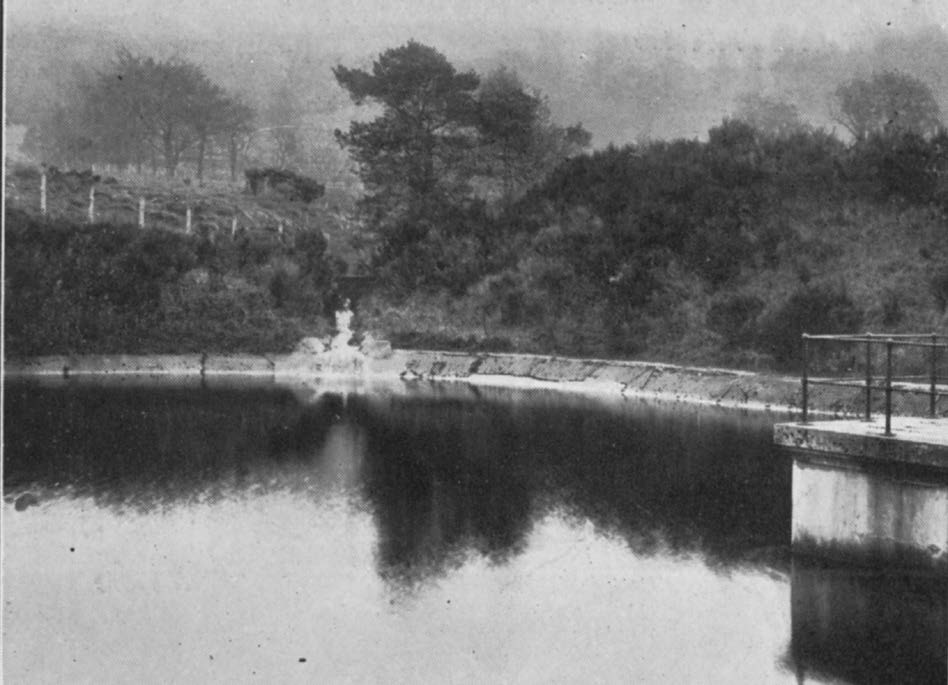

No description of Craigellachie Distillery would be complete without a reference to the wonderful purification plant, invented by Mr. R. Littlefield, of Exeter, and installed by Messrs. Mackie. The disposal of residual products of this distillery is a serious problem. Distillers are forbidden to discharge into the River Spey, or any of its tributaries, anything that will pollute the waters, and officers of the Spey Fishery Board visit distilleries frequently to see that the regulation is obeyed.

The process is of absorbing interest. Pot- ale, or residue left in the wash-still, which contains much solid matter, is pumped into a large tank. The spent lees, or residue remaining in the low-wines still, steep water, and washings are pumped into another large tank. From these, after being mixed with milk of lime to neutralise the acidity and diluted with water, the pot-ale, spent lees, and other residual liquors are run into settling beds of sand. When the solid matter settles gradually to the bottom, the remaining liquid is drawn off to filter towers, forty feet in diameter and twelve feet deep, filled with coke, which acts as a filtering medium. The liquid is sprayed gently over the coke by means of revolving spargers, and passes slowly through the towers into a Dortmand tank, whence it goes through sand and gravel filters before finally being discharged into the burn. The towers are inoculated with bacteria, so that in addition to filtration there is septic action. The semi-solid matter in the sand beds is drained of water, and ultimately carted away for manuring purposes. To see the effluent as it leaves the distilling apparatus, and again as it leaves the filtering towers to join the sparkling burn in the form of pure water, and runs joyously down the hill to the River Spey, is a fascinating experience. Craigellachie is one of the few distilleries in the country in fortunate possession of this type of purification plant.

The normal weekly output of Craigellachie- Glenlivet Whisky is from 4,000 to 5,000 proof gallons. The present warehouse accommodation is over 9,000 casks, and the firm propose to add another large warehouse in the near future.

Images © The British Library Board