LXXXIX

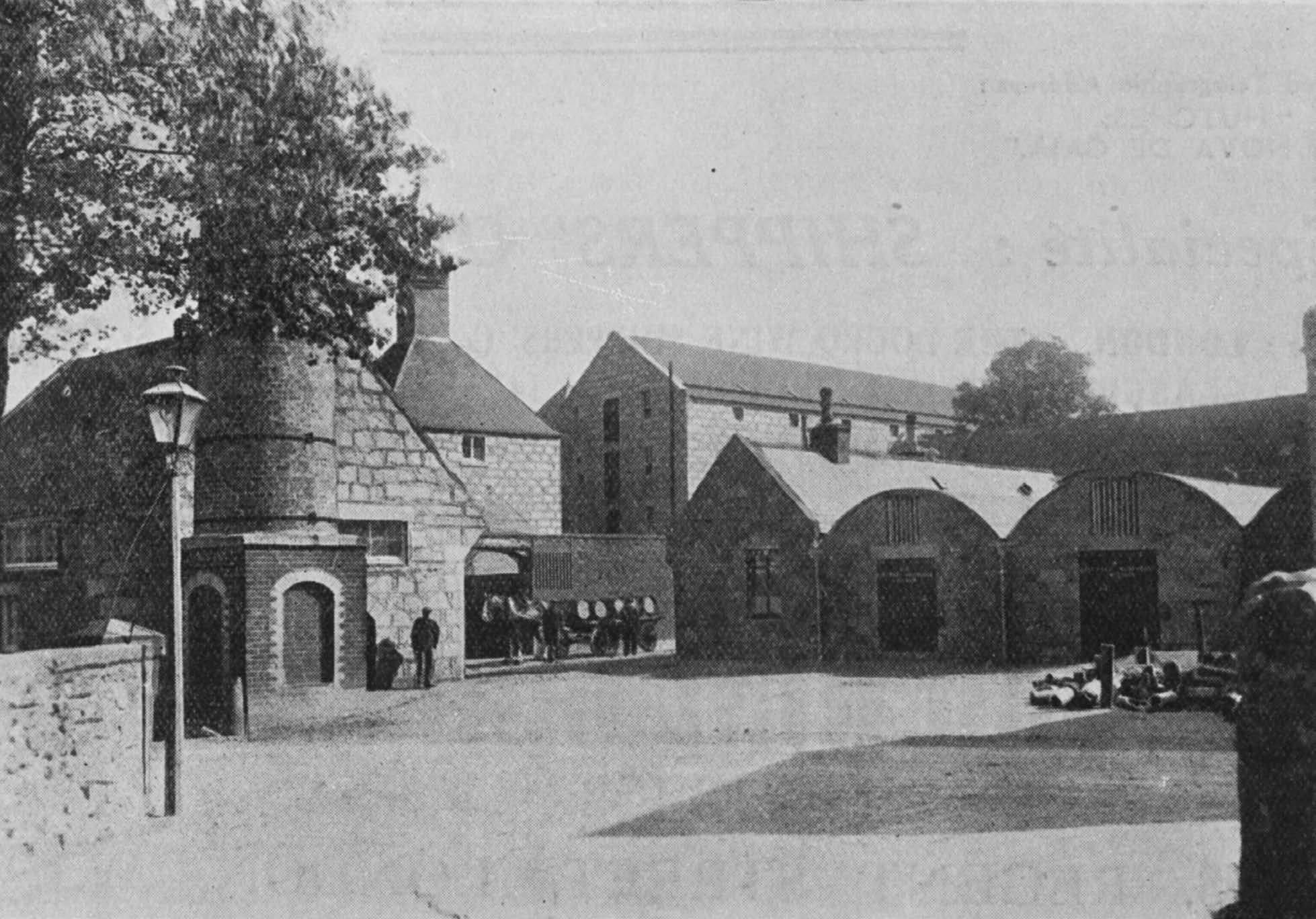

Glengarioch Distillery, Old Meldrum (Aberdeenshire)

September 14th, 1925

For a hundred and thirty years the well-known distillery at Oldmeldrum, in Aberdeenshire, has produced the Glengarioch brand of Scotch Whisky, and sent it in large consignments to all parts of the world. Oldmeldrum has not played a very conspicuous part in Scottish history. So far as can be ascertained, the chief event in the burgh’s chronology was a visit of Robert the Bruce with his army some hundreds of years ago, when he fought and defeated the Earl of Buchan’s Army on the 22nd May, 1308, on the west side of the Hill of Barra, now known by the name of North Mains of Barra, and within one mile of the distillery. Although the burgh has taken no leading part in the nation’s affairs, the town is by no means of mushroom growth, as the following particulars drawn up by Sir John Sinclair will show: –

The Statistical Account of Scotland drawn up from the Communications of the Ministers of the different Parishes, By Sir John Sinclair, Bart.,

Vol. Thirteenth.

Published MDCCXCIV.

(1794).

Parish of Meldrum.

(County and Synod of Aberdeen, Presbytery of Garioch.)

By the Rev. Mr. Thomas Tait.

The ancient name of this parish was Bethelny.

The air is healthy and the soil in general good.

There the town of Old Meldrum is situated, the soil is strong rich loam above clay.

There are several quarries of granite to be found in the parish.

There are no small riverlets in the parish, but such as take their rise in it, and yet there are three meal mills in it, mostly driven by water power.

Old Meldrum was erected by charter into a burgh of barony in 1672. The Baillies, two in number, are elected by Mr. Urquhart, of Meldrum, the Superior of the Burgh.

The inhabitants number about 783.

There is a Distillery and a Brewery lately established and both in a thriving way.

Minister’s Stipend £45, and 3 charters of victual, ½ meal, ½ barley.

Glebe measures between 8 and 9 acres.

Number of Poor receiving alms 30.

Schoolmaster’s Salary £10, but with emoluments may receive £30 to £40. School attended by 40 or 50.

Of late years the quality and size both of black cattle and horses has greatly improved and number increased.

The plough now made use of by many is of English form drawn by 4 horses or oxen.

Land is rented by the inhabitants from £1 to £2 the acre in general.

A considerable quantity of grain is sent yearly to Aberdeen market.

The inhabitants of Old Meldrum are well supplied with fine spring water, and the Distillery and Brewery have each the command of a small stream of water.

Owing it is thought to the quality of the water, the porter brewed here is in great repute.

The great disadvantage the people of Old Meldrum labour under arises from want of fuel, but if the duty was taken off coal, this will encourage the manufacturer and farmer and prove a great benefit to the poor.

The people in general are active and industrious.

The Glengarioch Distillery is without question the most imposing building in the locality, and it would not be too much to say that it give the old burgh its only industry apart from the surrounding agriculture on which the majority of the inhabitants obtain a livelihood.

THE ORIGIN OF THE DISTILLERY.

The chronology of the distillery is somewhat vague, but the brief records show that the business was established in 1794 by an enterprising and highly-respected Scotsman named Manson, and that Whisky was successfully distilled there for a number of years, during which its popularity gave practical expansion to the demands made on its resources. But in due course the name of Manson ceased to be identified with the distillery, as some years ago the business passed out of the hands of the founder’s family into those of Messrs. J. F. Thomson and Co., Ltd., and by them was sold in 1921 to the Glengarioch Distillery Co., Ltd., of which the present directors are Messrs. W. M. Sanderson (managing director), Leith; Mr. A. Crawford and Mr. A. N. Murdoch, Glasgow; and Mr. K. W. B. Sanderson, Leith, for whom Mr. William Marshall has for the last three years been the manager and secretary.

As to the general character of the distillery, it rightly claims to be one of the oldest of those devoted to the manufacture of pure malt Whisky in Scotland, and with respect to its capacity it need only be stated that it is equipped with all modern appliances, and that when in full operation it gives employment to fourteen workpeople in various grades. The original Mansons were, it is stated, also associated with a local banking business, and some descendants are still residing in Oldmeldrum.

Mr. Marshall enjoys a good distillery record, having been trained in the business from his youth. Prior to taking over the management of the Glengarioch enterprise he was for eleven years on the staff of Messrs. W. P. Lowrie and Co., Ltd., at their well-known place at Convalmore, Dufftown, Banffshire.

THE DISTILLERY AND ITS PROCESSES.

Roughly the Glengarioch Distillery covers four acres of ground, and for the most part its walls are constructed from that quasi-unperishable material known as “Aberdeen granite.” Though hidden in a comparatively obscure corner of Oldmeldrum, it occupies an outstanding position, and its high chimney shaft is a conspicuous land mark for miles round. Nearly a quarter of the total area is occupied by the malting department, which in all senses is up-to-date, and whose motive power is supplied by a 12 horse power Campbell oil engine, which, according to Mr. Marshall, has had an unbroken run since 1897 and shows every sign of rendering further usefulness to the company.

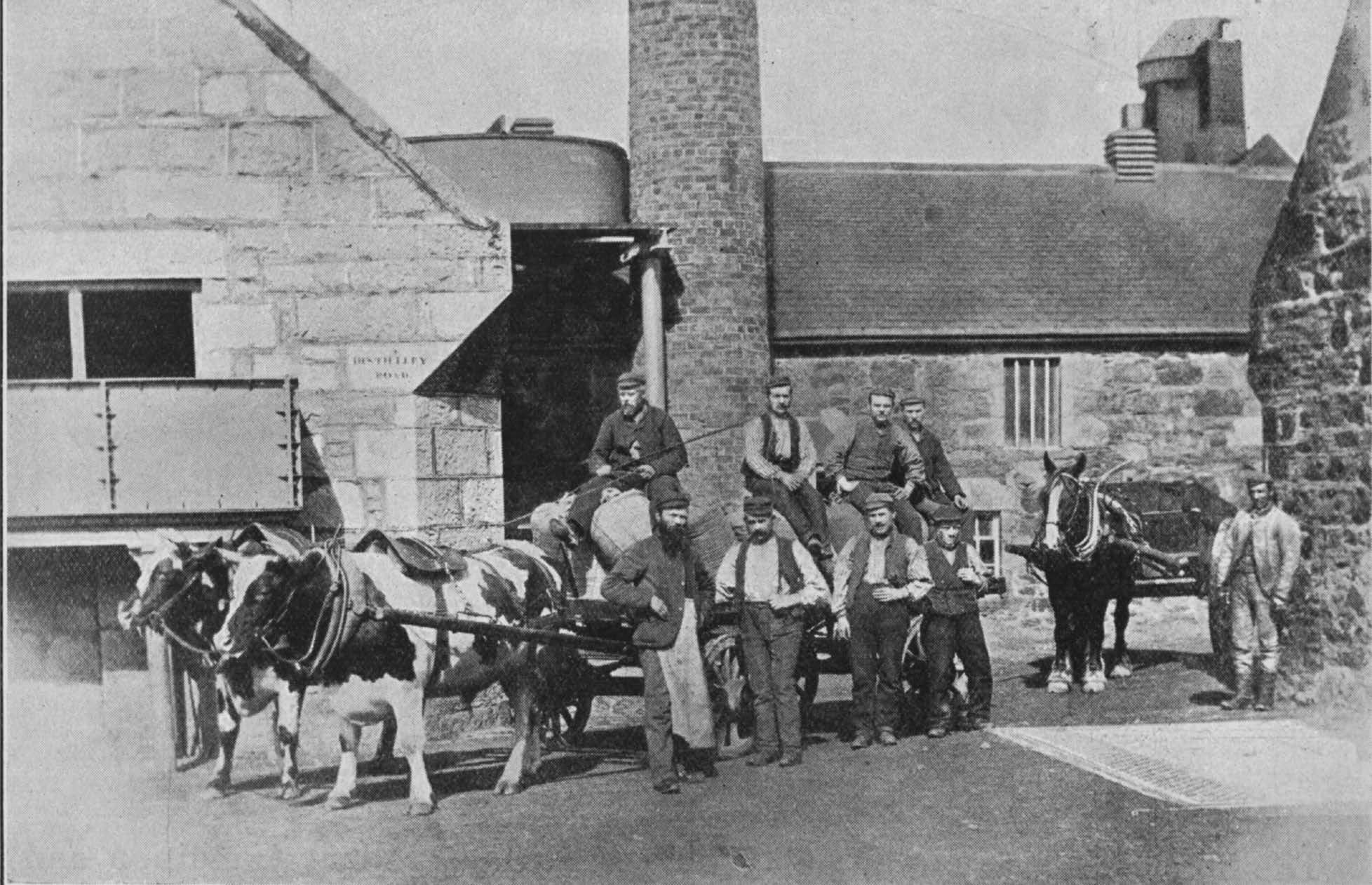

The barley used is grown in Aberdeenshire. Confinement to the country-grown cereal is almost a tradition with the distillery owners, as is borne out by the fact that from thirty to forty years ago the barley was delivered at Oldmeldrum by ox-wagon (as will be seen by our illustration). But, tempora mutantur. The fruits of the barley harvest are now brought in farmers’ carts or by the motor lorry transport, and during the deliveries the local traffic is by no means negligible.

Some notion of the requirements in grain may be formed when it is stated that within recent years the deliveries have averaged 150 quarters a week. In order efficiently to cope with this enormous supply, extensive capacity is necessary. There are three storage floors, each of about 550 square yards – and, it should be explained, the malting floors are of precisely the same area.

From the storage department the grain is delivered by elevators to the cleaning machine on the top floor; and, after being cleaned, is passed on by automatic appliances to any one of the three storage lofts on the second storey. At the ends of these floors are cast-iron steeps, into which the barley is deposited for saturation with water, and in these receptacles it remains for, roughly, seventy hours, when it is transferred to the malting floors for the purposes of germination. Thus it remains for twelve or fourteen days, when it is transferred to the kiln.

It should be stated that the malting floors are of concrete and kept scrupulously clean. In this section of the distillery the barley is kept for two days in what is known as a “couch” to induce germination, which is brought about under a temperature of from 55° Fah. to 60° Fah., according to the natural condition of the season.

From the couch the barley is turned out by the workmen with wooden shovels and spread over the floors, where it remains till the culms-growth is mature and at this stage called malt. The malt has by this time reached a stage when it may safely be conveyed to the malt-kiln to be dried, and this operation is rapidly performed with elevators and conveyors. It may be of interest to learn that the drying process is commenced at a temperature of 110⁰ Fah. and is usually completed at 160⁰ Fah. The drying process is chiefly carried out with malting coke obtained from Swinehill, near Falkirk. This essential accessory of the distillery is valuable by reason of the absence of fumes. But peat is also used for drying the malt, and in this process the Whisky obtains its peaty flavour. The drying of the grain usually occupies about 48 hours, so that there is ample time for what may be described as the impregnation of the flavour which makes Whisky so popular.

The floor of the drying kiln is about 192 square yards. From this department the grain is transferred through a shute to the malt deposits, where it remains for about three months to allow it to “ripen.” There are three deposits, each with a capacity for 700 quarters. The grain is next conveyed from the deposits to the crushing mill, through an automatic weighing machine, at the rate of 40 quarters an hour. Then, in its bearded state, it is passed on to the culming machine, which removes the culms and leaves it in a condition to be passed over the iron rollers to be crushed. Next the grain is passed through a screw and elevators to the ground malt hoppers, which are situated over the mash tun.

In the mash house are two steam engines – one of 14 h.p. for heavy work and the other of 6 h.p. for light work. The larger engine works the malt mill and provides power for the pumps and the stirring gear of the mash tun, while the smaller one operates the switchers in the wash backs. Each tun is provided with a revolving switcher which, when in operation, keeps down the air bubbles and promotes fermentation.

In the mashing machine the malt is mixed with water and then passed on to the wash tun, which has a capacity of 250 bushels per mash. After the mashing process, the saturated grain is allowed to settle and the liquor is drained through a perforated bottom to what is known as the under back. By that time it has become wort, and as such is pumped up to a receiver or tank. Afterwards it is passed into the refrigerator, in which water is turned on to bring the wort to the desired temperature, and then comes the process of fermentation, which occupies the resources of five vats. There the yeast is added – it is chiefly from Edinburgh brewers – and the fermentation occupies about 60 hours.

In the next stages of manufacture the boiler and still house occupies an important part. There are one boiler and two stills – one a wash still and the other a low Wines still. The liquor is removed from the wash charger to the wash still, where it is heated by a coal fire, and in due course transferred as vapour through copper worms, in which it is condensed and then runs to the spirit safe and thence on to the low Wines and feints receiver. It is next pumped to the feints charger, and passes into the low Wines still, whence it is returned to the spirit safe. The first of the run is known as foreshot. The liquor has by this time become spirit, and it is tested by water until it reaches the desired purity, when the flow is turned on to the spirit receiver and is allowed to run until it nearly reaches the stage known as “proof,” when the flow is again turned on to the light Wines receiver, to be redistilled – and the distillation process comes to an end.

The Whisky is then removed to vats in the Spirit store, where it is poured into casks of an average capacity of 55½ gallons, and these are placed in the warehouse to remain for maturing – from seven to ten years, according to the fancy of the purchaser.

It should be mentioned that the capacity of the wash-stills is about 2,500 gallons and of the Spirit still about 2,000 gallons.

THE SCENE IN THE WAREHOUSES.

Some idea of the spectacle presented by the warehouses may be formed when it is stated that the stock at the time of our representative’s visit number 7,000 casks. The whole of this enormous stock belongs to different customers, and is being despatched to various parts of the world as required. It is of interest to note that the Glengarioch Distillery, like many other highland Whisky distilleries, closed down from the end of May till some time in October, and that Mr. Marshall then took the opportunity of a thorough overhaul of plant and machinery for next season’s operations.

In conclusion it may be stated that the distillery is full of historic interest, but that when the original company went into voluntary liquidation on transfer the records were either destroyed or mislaid; therefore the more important chronological steps of the Mansons and their successors can only be a matter for vague conjecture. All that is known for certain is that the distillery was remodelled in 1901, and that since that year its operations have been conducted with profitable results. The accompanying photographic views furnish an excellent idea of the distillery and its principal internal features.

Images © The British Library Board