LVI

Glenlossie-Glenlivet Distillery, Near Elgin

August 14th, 1924

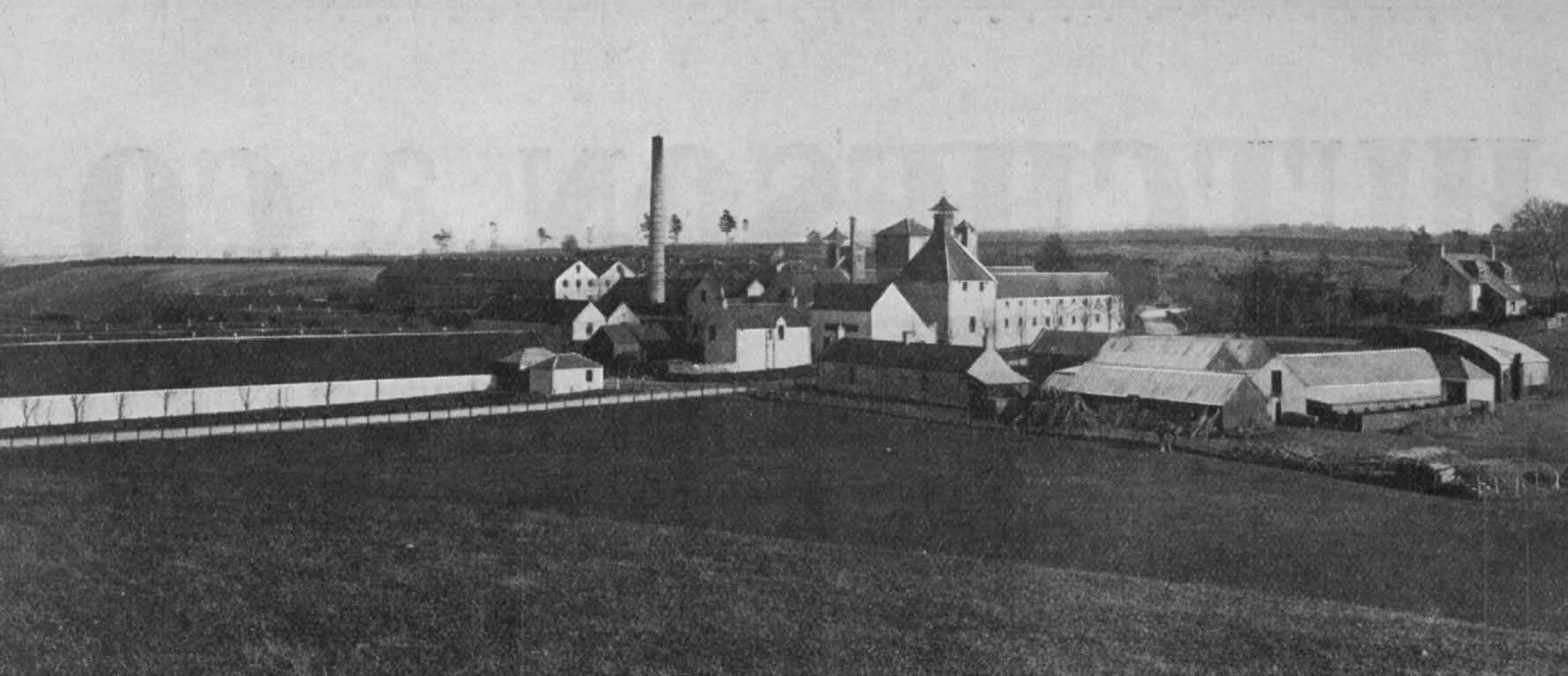

Glenlossie Distillery takes its name from the Lossie, a beautiful river near the town of Elgin, and which enters the Moray Firth at the port of Lossiemouth. The premises stand in a hollow below a fir-clad hill four miles from Elgin, and the surrounding scenery, with a background of hills and a vast plain of pastureland stretching towards the Moray Firth, makes the site one of the most charming in a district justly celebrated for its beauty.

At Glenlossie the buildings have a particularly pleasing appearance, due mainly to the lavish amount of green and white paint that is bestowed upon them during the summer season. The zeal of the management for cleanliness and smartness is by no means confined to the exterior of the establishment. To take two examples at random, we have seldom seen a still-house or receiver room so neatly arranged and so spotlessly clean as those of Glenlossie.

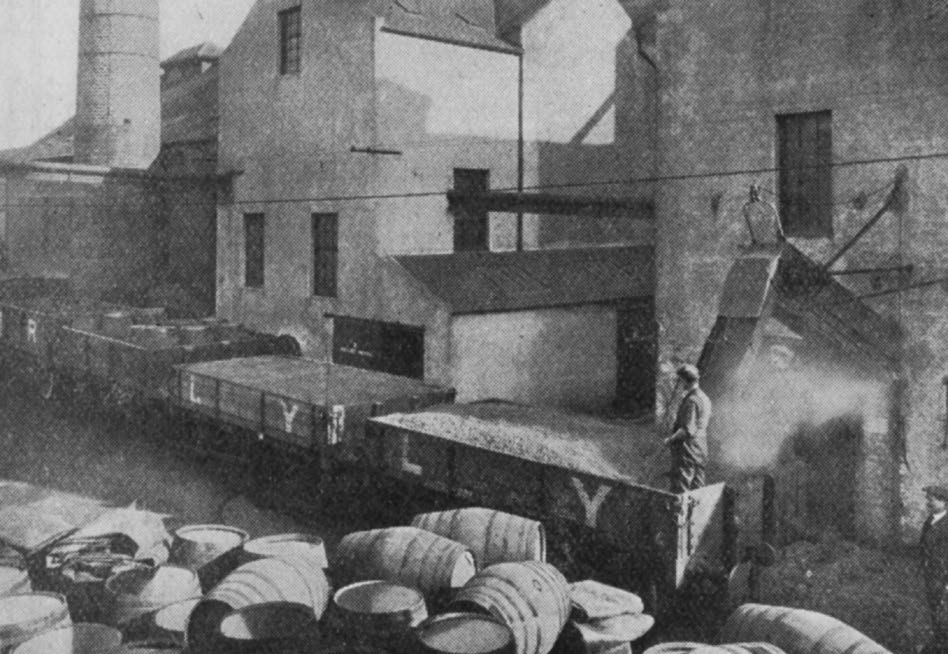

With considerable enterprise the firm have constructed a siding over a mile long, which extends from Longmorn Station to the doors of the distillery. By this means barley and stores of various kinds are brought directly into the premises. The maltings comprise three immense germinating floors topped by two barley lofts. An elevator takes the barley to a screening machine before it is further conveyed in the four steeps varying from 35 to 45 quarters capacity. The usual mixture of peat and coke provides the fuel for two kilns floored with metal plates. Both furnaces are controlled by patent regulators, and stored for dried malt is provided by four malt hoppers capable of holding 250 quarters.

A Jackson’s mill performs the grinding operations, and there is a recently-installed screening machine which has successfully prevented any explosions in the mill-room. Power for the malting and mashing plant is provided by an excellent Tangye oil engine, and there is also a Marshall steam engine and dynamo for generating electric light.

The quantity of malt mashed each week is 2,700 bushels, and the mash-tun is fed from four large grist hoppers. Draff can be removed from the mash-tun by a drag to be sold wet or put through a draff-drier and taken by fan to a dried-grain store.

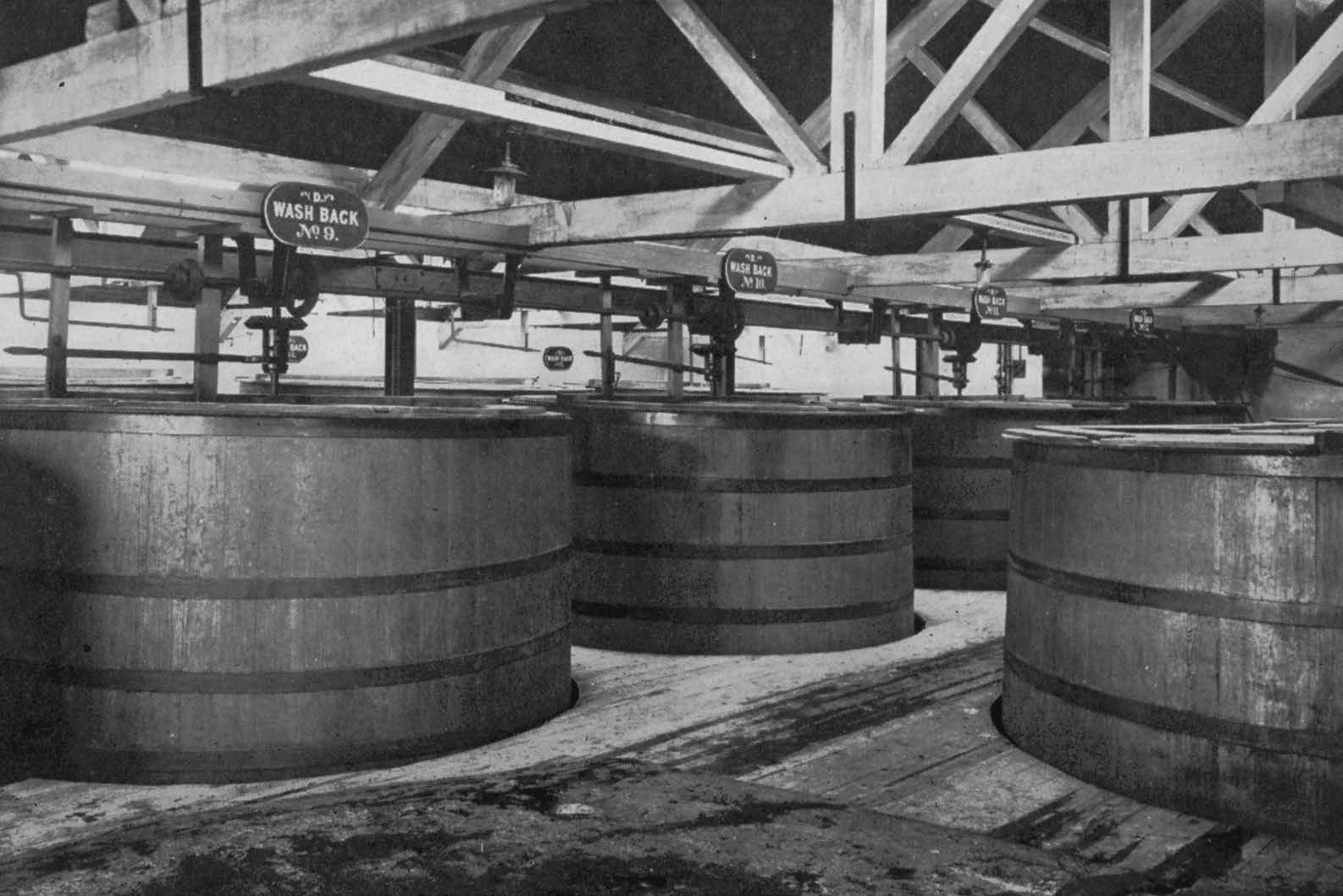

The tun-room contains twelve wash-backs, varying in working capacity from 3,000 to 4,500 gallons. In addition to the Tangye oil plant, there is a water-wheel and another driving steam engine, making three sources of power.

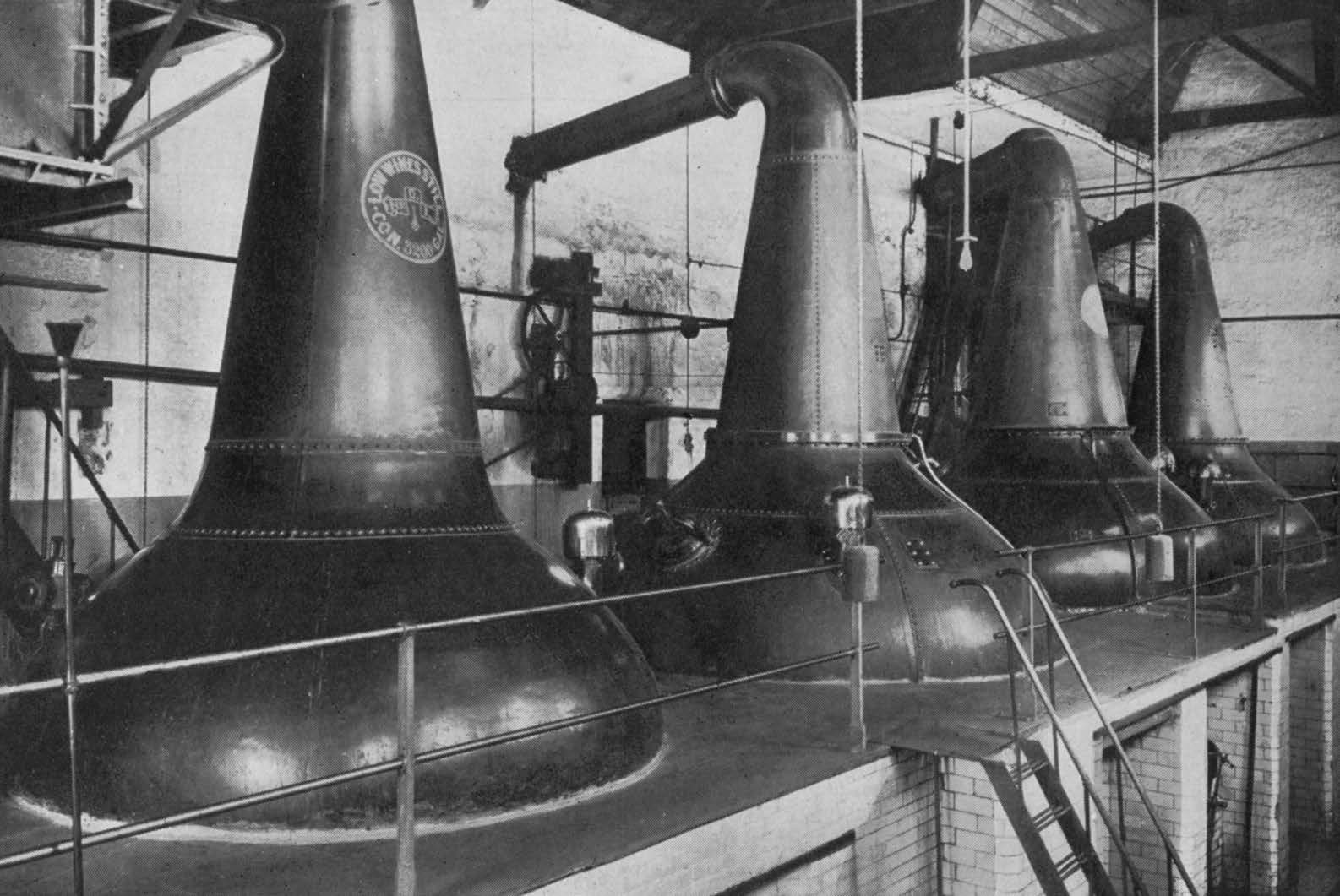

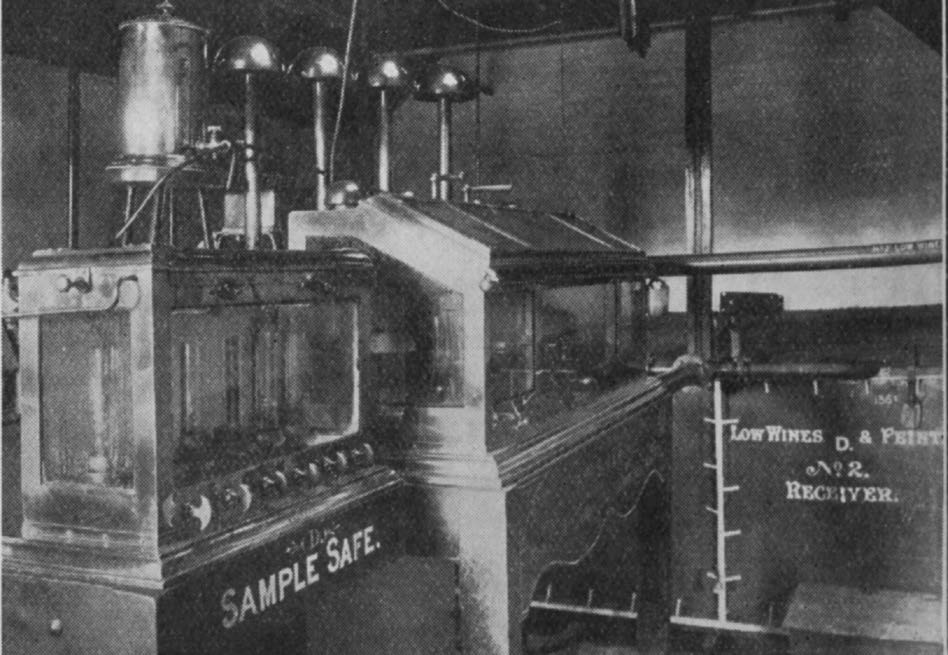

Four stills fitted with air and anti-collapse valves occupy the still house, already referred to as one of the finest buildings of its kind in Scotland – spacious, well ventilated, and superb in appearance. The capacity of the wash-stills is 4,100 gallons in each vessel. Off the still-house is the receiver-room, containing the usual appliances polished until they almost dazzle the eye. There are two sages: one with four air-valves and a smaller sampling safe.

The average output of Glenlossie-Glenlivet is 6,000 gallons weekly, and the normal contents of the warehouses amount to 9,000 casks. For disposing of effluent, bacteria towers are employed with great success.

The proprietors of Glenlossie Distillery are the Glenlossie-Glenlivet Co., Ltd., of Edinburgh.

Images © The British Library Board