XXXV

John’s Lane Distillery, Dublin

November 14th, 1923

A way back in the dim and distant past, long before the Norman set his foot upon the soil of Ireland, the distilling trade of Dublin was in active existence. It is to-day one of the most important industries of the city; and its fame is as well sustained now as ever, despite the many adverse factors it has had to encounter. If that be so – and there is good authority for it – the statement of a leading industrial writer of to-day acquires a new significance – that distilling is now “one of the chief Irish industries, and the fame of Dublin Whisky in particular is world wide.”

To write adequately of the early industry of the distilling industry is to write of a series of extraordinarily interesting transactions, including a succession of vexatious exactions on the trade. Indeed, a few of these facts may, in passing, be worth noting.

About the reign of Henry VIII. the State – England – began to be seriously interested in the manufacture of Spirits in Ireland. Strange it is, that the ordinary text books of history do not record how this monarch, his courtiers, and statesmen got it into their heads that Irish Whisky could be turned into a great source of Irish revenue, which continued with excellent results even to our own time. The first definite impost that we really are aware of dates from the year 1662, when a small duty of 4d. was imposed upon every gallon of Spirit manufactured in the kingdom.

That the art of distillation in Ireland has reached a high state of perfection before the stirring times of the Tudor kings, may be taken as certain; for we are told that the industry was so important in those days that it was put under severe restrictions. Indeed, the name “uisge heather” given to it apparently by the Normans, came under the scheme of English taxation.

Doubtless many of us have heard of the six-and-eightpenny fee which in our time the solicitor asks of his client, but few of us are aware that this is the early history of Anglo-Irish Excise and Customs. Henry VIII., whom Holbein has rendered immortal in his famous, but fearful, masterpiece, lives also on the canvas of history as the originator of that historic 6s. 8d. Highly domesticated as he was, with growing household expenses everywhere surrounding him, he, in commune with one of the Cecils, found out that aqua vitæ in every “Irish town could and should pay him 6s. 8d. for every maker.” Needless to say that this impost was the foundation of our licensing laws. Under statute passed at Drogheda, it further appears that no person could make or distil any aqua vitæ under penalty of fine and imprisonment, except under licence obtained from the Lord Deputy.

Well over one hundred years ago there were about 200 distilleries in Ireland. In 1922 there were only 21 but this diminution does not by any means represent a decline of the industry. As a matter of fact, the output has increased. Two years ago upwards of 13,000,000 gallons were distilled, whereas in 1800, the year of the Union, the output was only 5,000,000. Viewed from the standpoint of national finance the importance of the industry is at once apparent. At the time of the union with Great Britain the duty on Spirits was but 2s. 5d. a gallon, while to-day the duty on every proof gallon of Spirits manufactured is 72s. 6d.

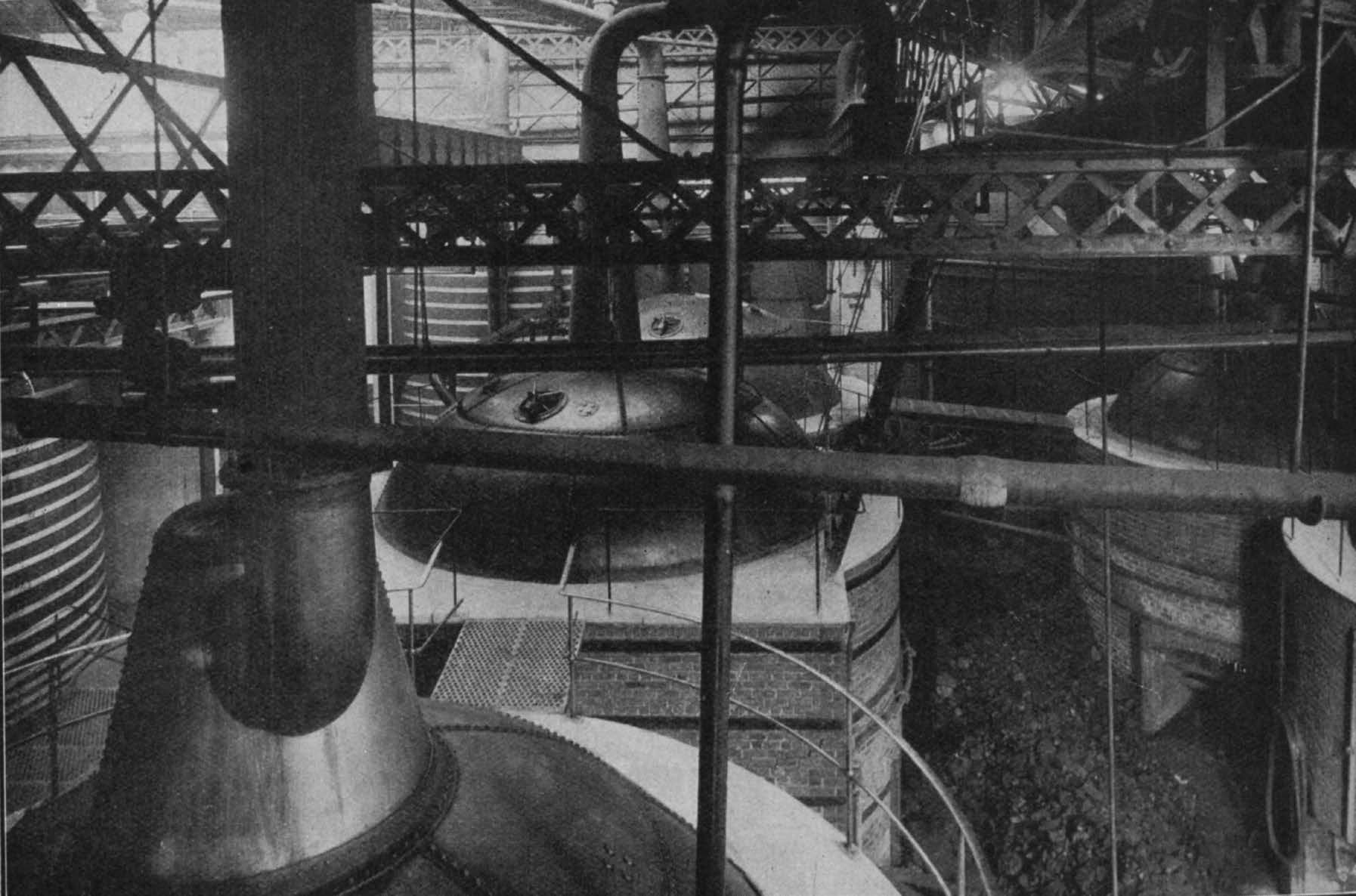

Patent as well as pot-still Whisky is made in Ireland, but this product cannot compare with old Irish pot-still. This is undoubtedly due to the materials used, the purity of the Vartry water employed, and the scientific skill and efficiency exercised in the process of manufacture. Irish pot-still Whisky is distilled in a pot-still from wash derived from the fermented wort of the finest home-grown malted and unmalted barley. It goes through three successive distillations in separate stills, popularly named the wash still, low-wines still, and the spirit still, before it can be called Whisky.

Patent-still Spirit is distilled from wash derived from the fermented worts of Indian corn, raw grain, rice and other materials capable of fermentation. With one operation, under steam- producing power, the patent-still is able to produce a tasteless, clear, elemental Spirit at or about 67 over proof, but devoid of secondary products and other essentials, portions of which are so necessary in the production of that mellow and pleasant taste found in Dublin pot-still Whisky. This is no place to enter into a dissertation on the merits and demerits of the pot and patent-still, but we only allude to the matter in passing to emphasise the value of Dublin pot-still Whisky,as compared with “silent” Spirit, which George Augustus Sala amusingly described some years ago as being: “A product which starts life without a character and fails to get one with age.”

That the name and fame of Dublin pot-still Whisky have reached two hemispheres cannot be gainsaid. Well might Dr. Frank L. Teed, Public Analyst for the City of London, speak in these terms of Power’s Irish pot-still Whisky (manufactured at the distillery now under notice) in giving his evidence in November, 1905, at a trial at Islington as to “What is Whisky?”: “I have examined and analysed, among other samples, that of John Power and Sons’ Irish pot- still Whisky, and testify that it has come up to my standard of real Whisky.” Again, the late Sir Charles Cameron, Professor of Chemistry and Hygiene, Royal College of Surgeons, Ireland, and President of the Public Health Committee of the Dublin Corporation, spoke thus: – “This Whisky has been distilled in the pot-still from the finest native malt and barley, and the brewing and distilling processes have been skilfully conducted. I consider it to be the finest Whisky I have ever examined.”

John’s Lane Distillery, which has belonged to the Power family since it was established in 1791, is one of the oldest in Dublin. Mr. James Power, who founded the distillery in the year mentioned, died in 1817. He was succeeded by his son John, a man of enterprise and energy. Owing to his great business activities the distillery during his lifetime assumed immense proportions, and now covers about eight acres, reaching from Thomas Street to the quays on the south side of the river Liffey. In 1821 John took his son James into partnership, and the firm have traded ever since as John Power and Son.

In passing, we may mention that John Power was High Sheriff for the City of Dublin in 1841, and in that year had the honour of a baronetcy conferred on him, when the firm traded as Sir John Power and Son. Upon the death of the second baronet in 1877, James Talbot Power and Thomas Talbot Power inherited the distillery property with the estate. Not many years ago they were appointed Irish Whisky distillers to the King.

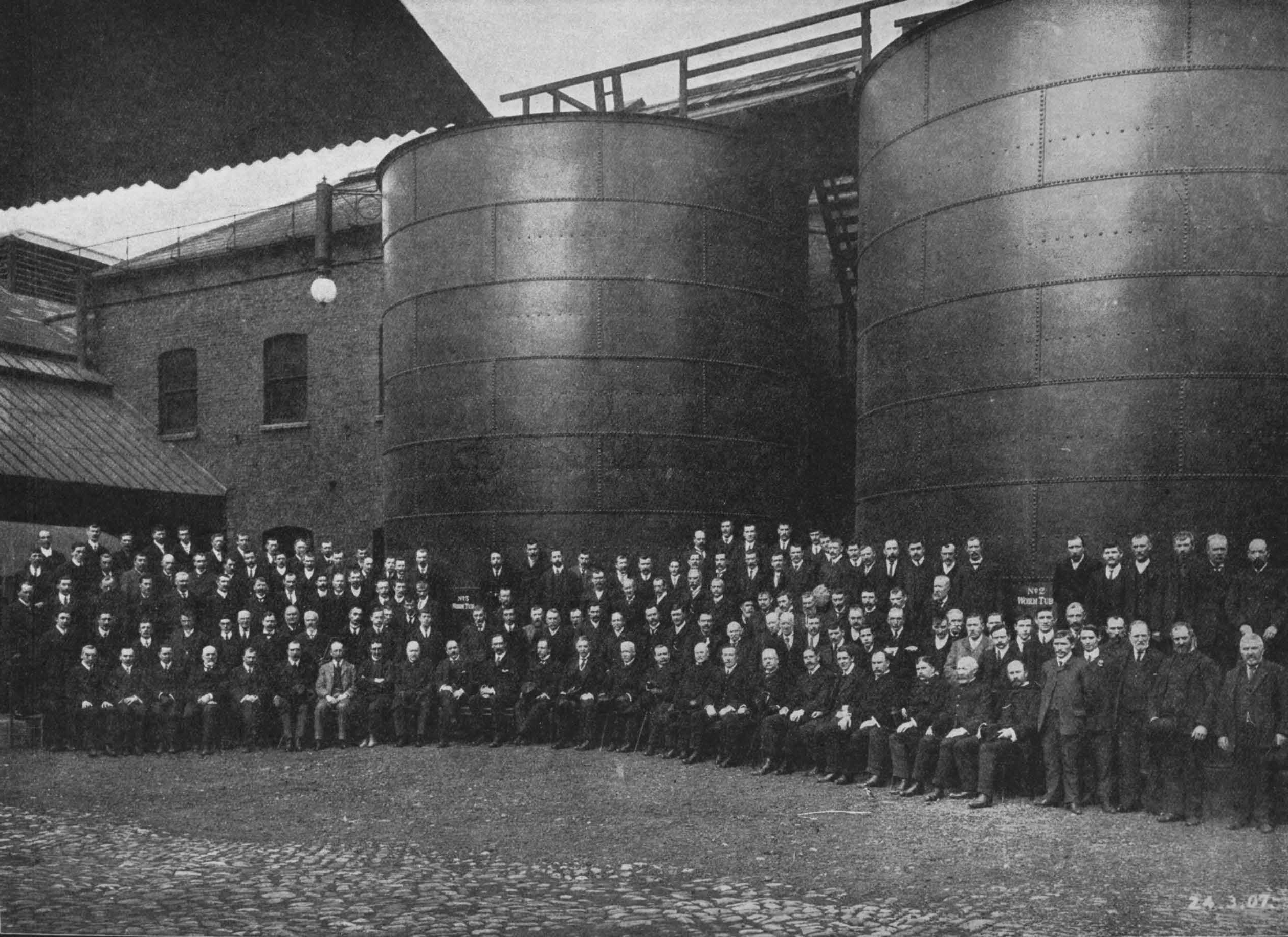

The buildings, whose frontage in Thomas Street forms an imposing block, consist of a counting-house, with distiller’s residence overhead, and offices for the Customs and Excise department, distillery works office, electric-light dynamo room, together with up-to-date lavatories and bathrooms for the use of the employees, of whom there are hundreds, and for many of whom the firm provide dwelling-houses adjacent to the distillery at very moderate rents. They also have the advantage of free medical attendance.

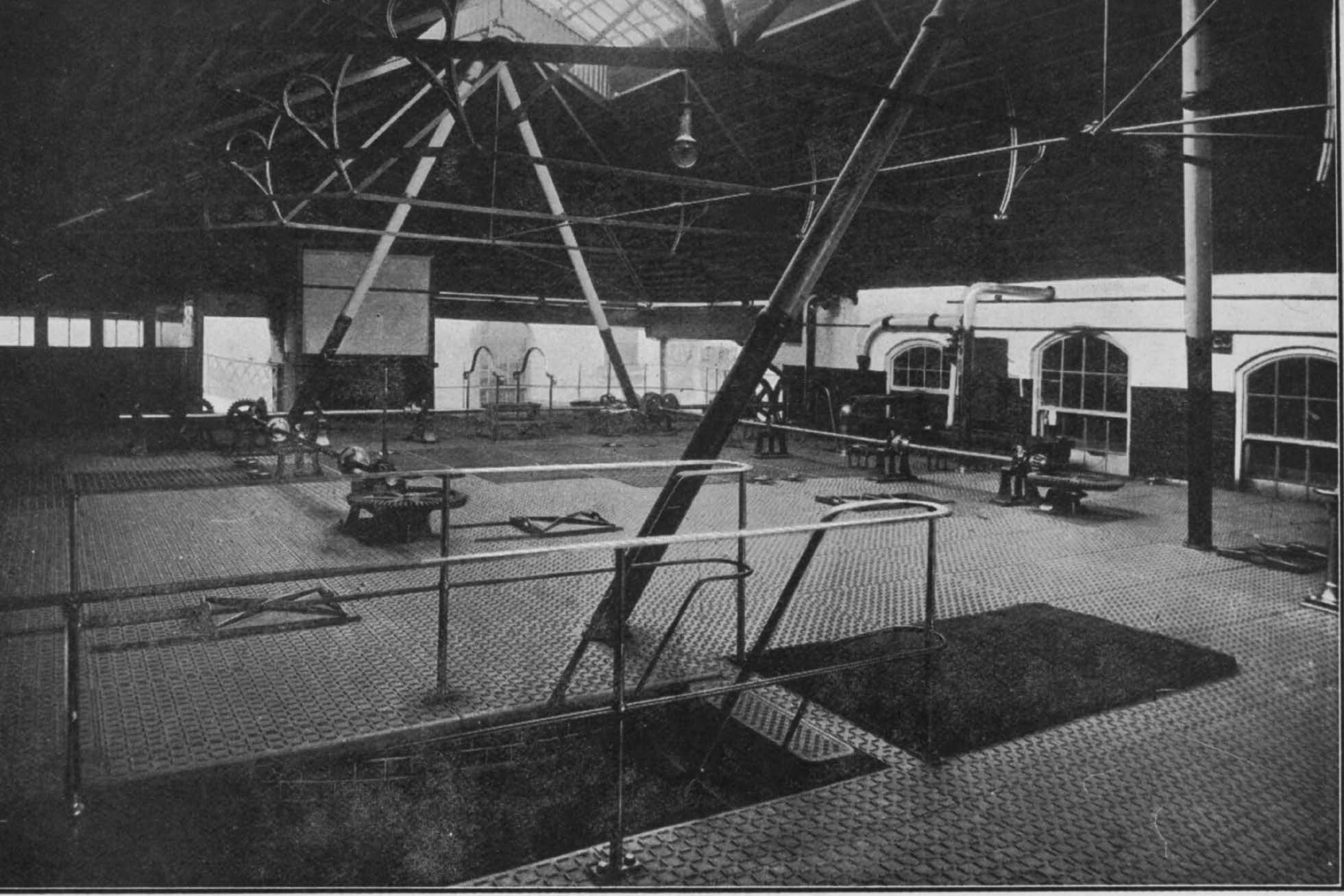

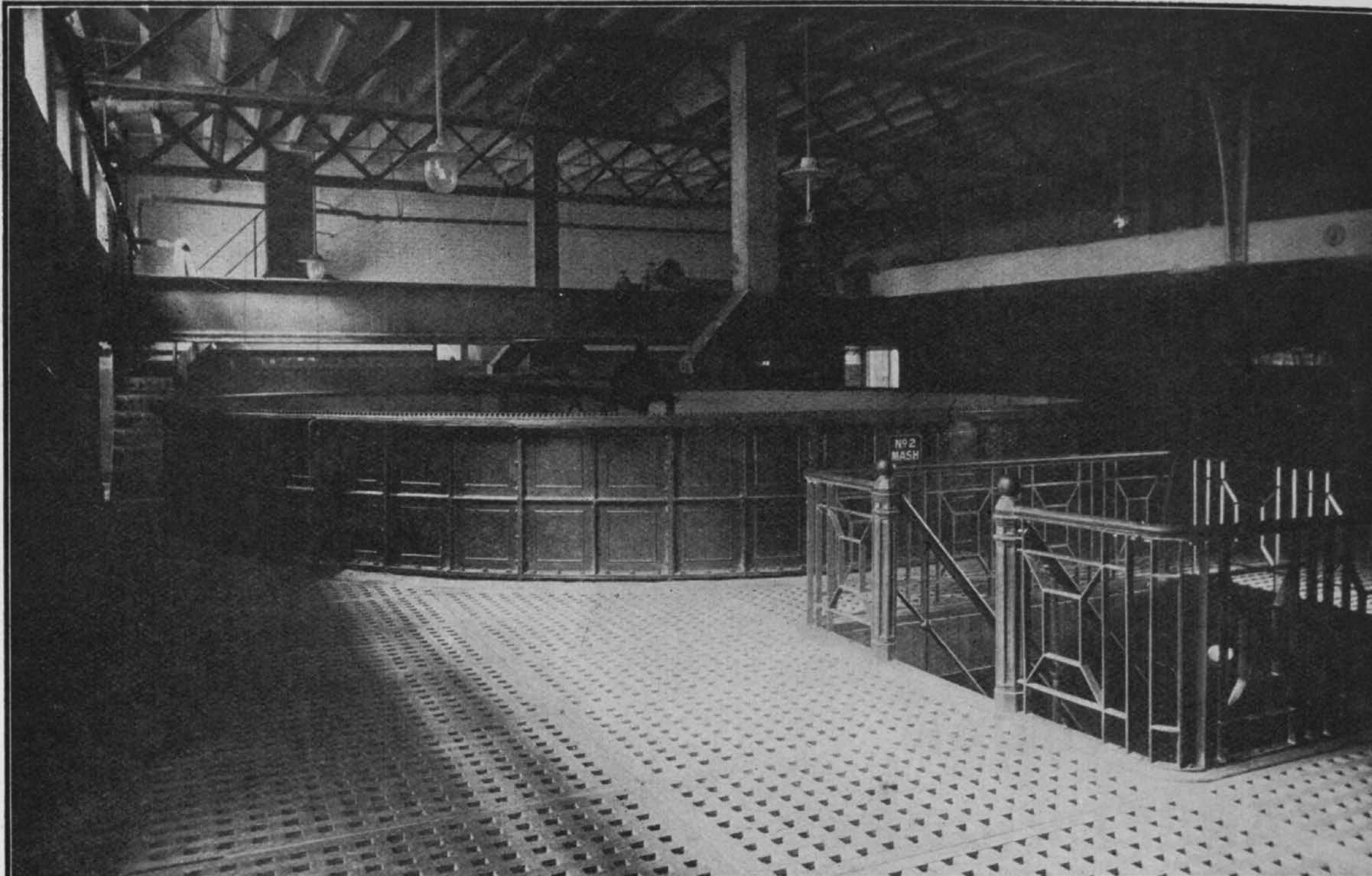

The mills and barley screens are of the latest and most-approved pattern; and the elevators, constructed of cast-iron plates, bid defiance to the progress of fire. The stores and malting rooms consist of five large floors in which from 30,000 to 40,000 barrels of barley are usually stored during the working season, which generally runs from September to June. The two mash tuns, each of about 34 feet diameter and eight feet deep, are said to be the largest of the kind in the world. A third – still larger – is in course of erection. These two tuns can deal with 94,000 lbs. of material at each mashing. There are four refrigerators and nine wash backs (each capable of holding a brewing of 40,000 gallons) in the fermenting room.

In the still house there are six pot-stills (no other description of still in use) each working off from 15,000 to 25,000 gallons. The low-wines and feints receivers and spirit receivers and safes are so symmetrical in shape and so perfect in position, arrangement and cleanliness as to have extorted eulogistic criticism even from the most critical of Government inspectors when on their annual rounds.

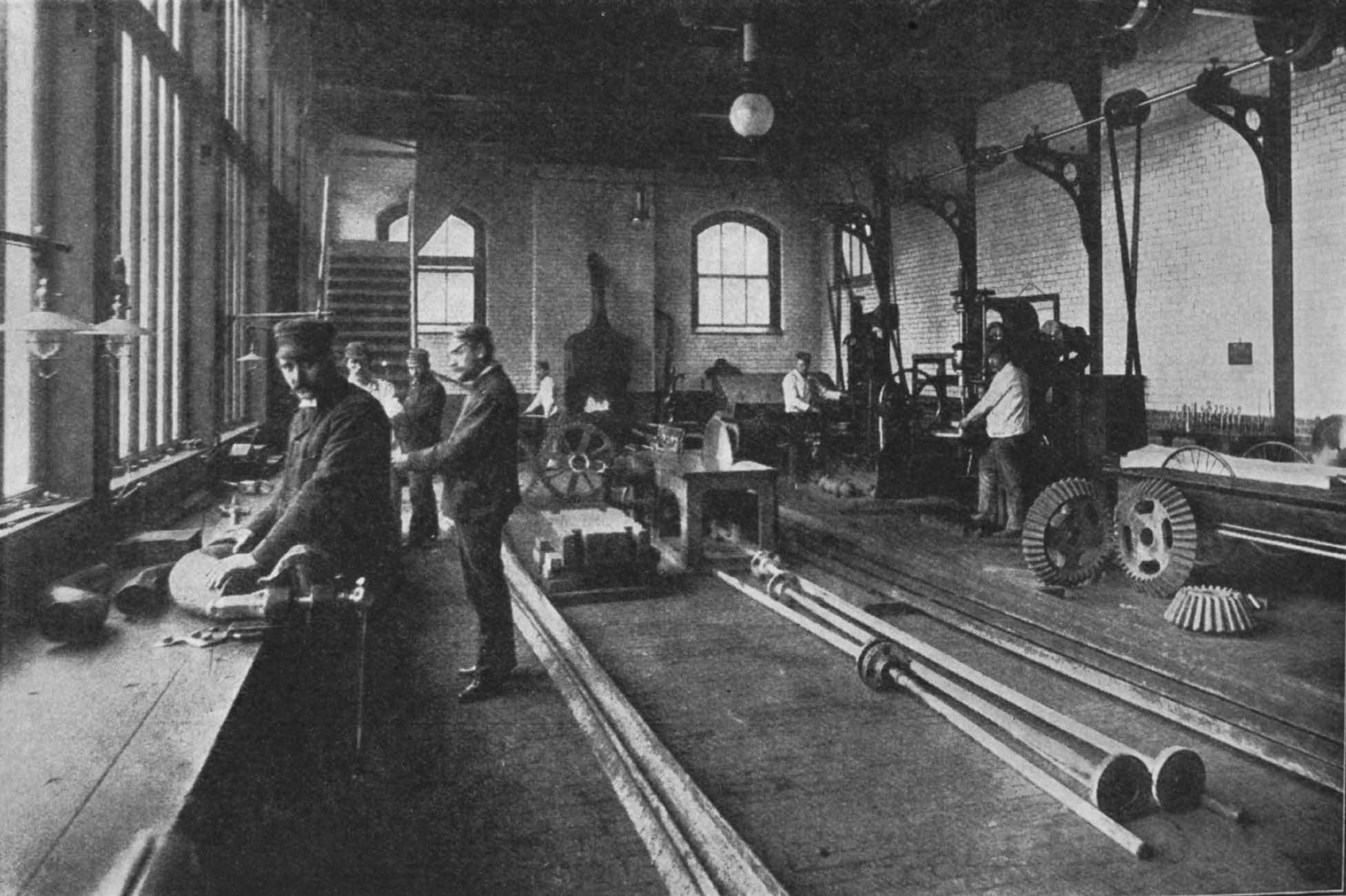

The daily consumption of coal is from 80 to 100 tons; and the annual output of Spirits is more than a million proof gallons. In the engine room there are five engines, two of which are McNaught compound engines, one of 400 and the other of about 250 horsepower, both made by Messrs. Turnbull, Grant and Jack, of Glasgow. A hydraulic hoist, by Messrs. Ross and Walpole, of Dublin, is worked by the overflow from the worm tubs; the ram is 22 inches in diameter, and 29 feet long. There are two Siemens’ dynamos, driven direct by two “Willens’” engines of 50 horse-power, each supplying current for 22 arc and 740 incandescent lamps. There is also a stationary, horizontal, double-acting fire-engine, one of the latest patterns of Messrs. Shand, Mason and Co., of London, capable of throwing 800 gallons of water per minute through eight lines of hose to a height of 150 feet.

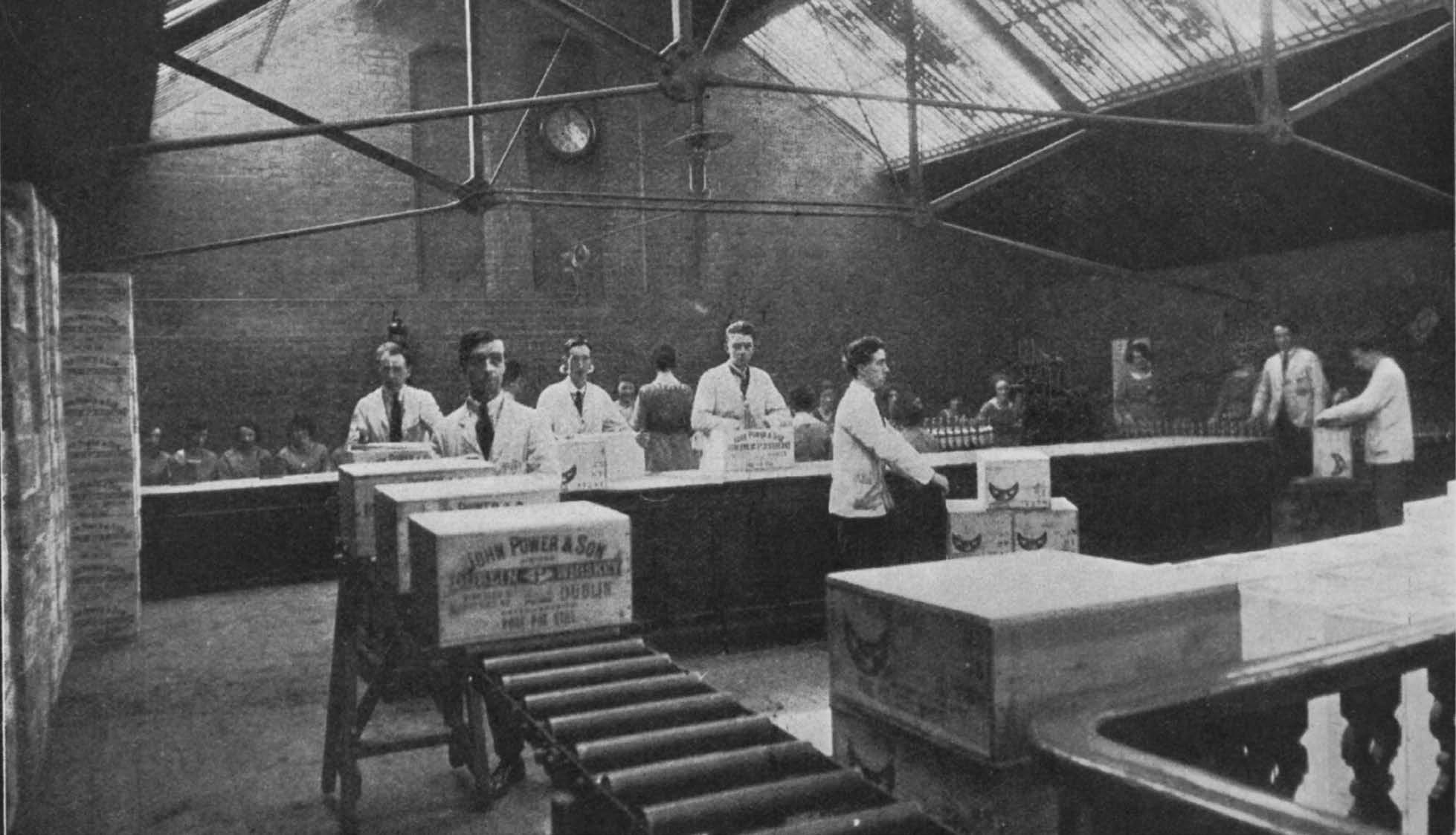

Besides the usual racking store – duty-paid – there are eighteen duty-free warehouses upon the premises, and two outlying duty-free warehouses, one under the South City markets, in which is the bottling warehouse, where the celebrated and well-known “Three Swallow” is bottled and despatched to all parts of the globe, and the other comprising twenty-one arches under Westland Row railway station.

These warehouses, which have accommodation for upwards of 40,000 casks, are in charge of the most experienced men, who not only look to the proper condition of the floors, but regulate the temperature of the vaults from week to week. No wonder that Power’s pot-still Whisky possesses purity, maturity, flavour and aroma; for apart from the scientific watchfulness exercised during the process of manufacture and stowage, the casks are not permitted to leave their maturing positions until the Spirit has reached the age of seven or even nine years.

The bottling warehouse in Drury Street, to which we have already alluded, is an immense department in itself. Here are carefully arranged vats of enormous capacity, each holding many thousand gallons of Whisky, from which the bottling is done by a large number of experienced hands under the supervision of the Excise officials. From the basement the bottled Whisky is conveyed by lifts to the packing department, where it is labelled, capsuled and packed into cases for shipment.

Within recent years – say a decade – the export of Whisky from Dublin has been close on two million proof gallons per annum. Before the Budget of 1909 the export value was more than £2,000,000. In 1913 the export reached even bigger volumes, and, needless to say, the old-established firm of John Power and Son – now in its one hundred and thirty-second year of trading with a member of the family still guiding its destinies – did a substantial share of that business.

May we add in conclusion that among the heirlooms in the Power family – and there are many – there are none more prized or more carefully preserved than the silver trowel with which Sir John Power – the first baronet – performed the ceremony of laying the foundation stone of the O’Connell monument in Glasnevin Cemetery, Dublin. This precious souvenir, presented by the O’Connell Monument Committee, bears the following inscription: –

“This trowel was used by Sir John Power, Bart., of Roebuck House, co. Dublin, 23rd September 1854, on laying the first stone of the O’Connell Monument.”

His victory in a glorious strife,

To feeling, faith and freedom dear,

Cost not one patriotic life,

A wound, an outrage, or a tear.

Images © The British Library Board