LXII

Longmorn-Glenlivet Distillery, Near Elgin

November 14th, 1924

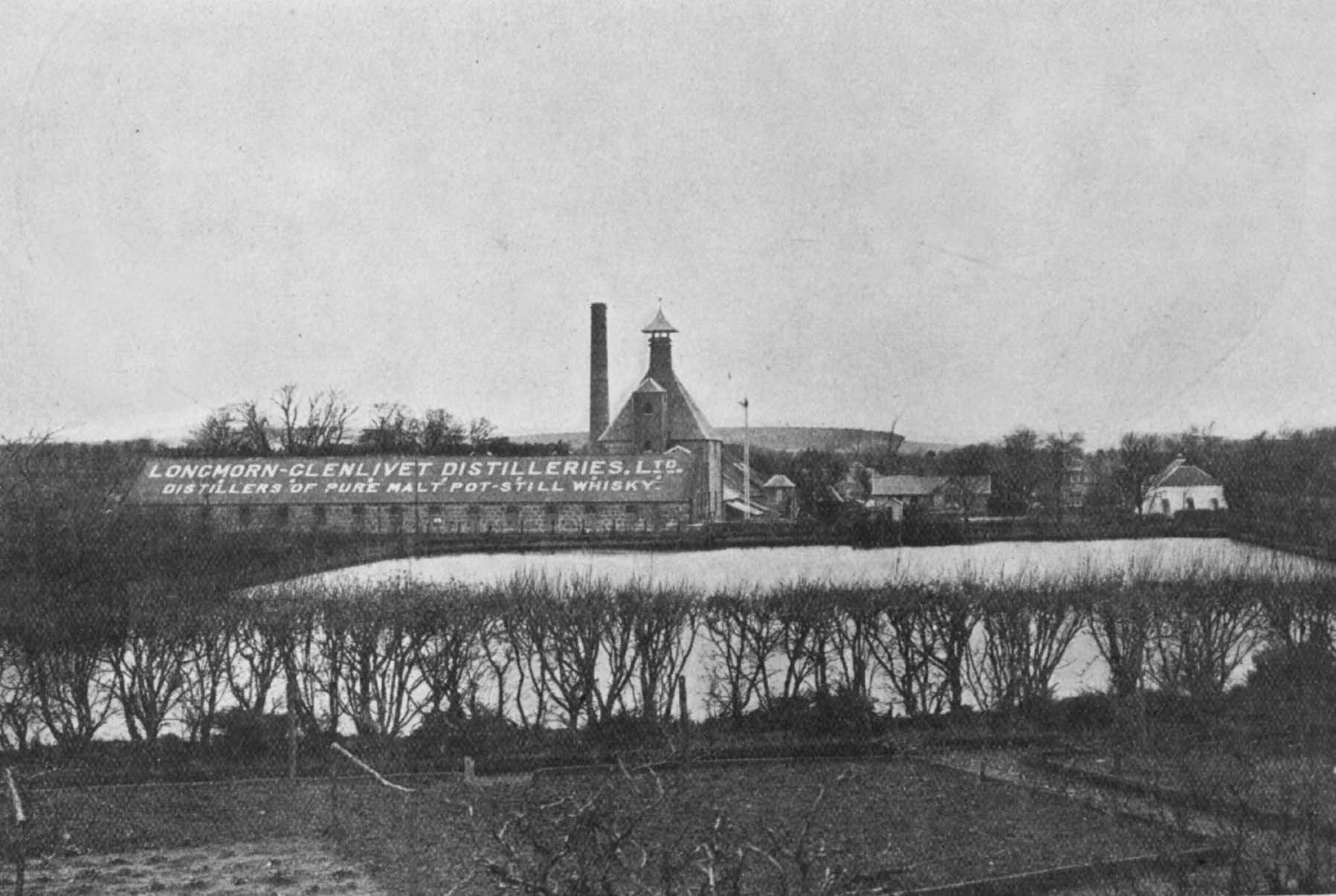

Erected in the year 1894, Longmorn-Glenlivet Distillery comprises an extensive group of buildings advantageously situated within a few yards of Longmorn Station, which is some four miles from Elgin on the main railway line from that city to Aberdeen. Three years after its foundation the business became a limited company, and has since continued to work under the name of “The Longmorn-Glenlivet Distilleries, Limited.”

The distillery lies on a large square site surrounded by open country, with fertile pasture land undulating in every direction, and distant chains of hills forming a rugged barrier on the north-westerly horizon. Flanking the premises are a number of picturesque little houses composing the hamlet of Longmorn, and most of these owe their existence to the two distilleries in the immediate vicinity, Longmorn and its neighbour Glen-Elgin, a mile southward, which also stands close to the railway line.

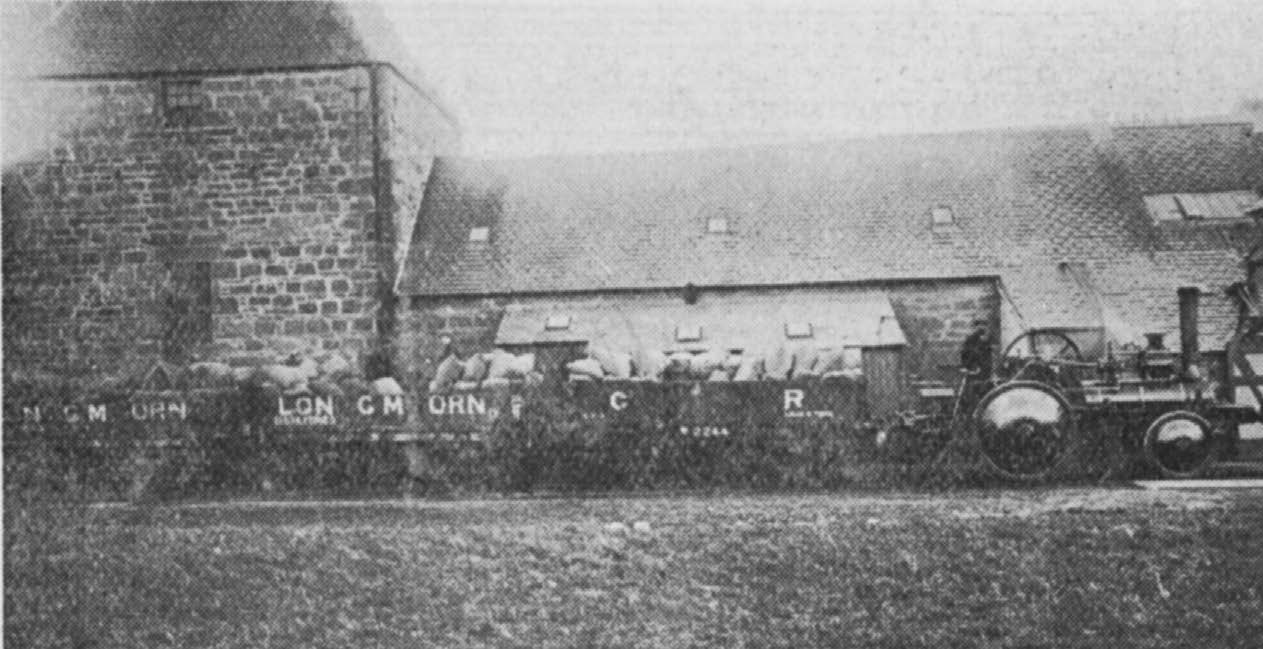

Longmorn Distillery is up to date in every sense of the word, and on entering the grounds the visitor sees proof of this in the form of the private locomotive which brings all supplies into an excellent siding on the premises. By this means the barley is brought to the door of the maltings, and the sacks are neatly tilted into a hopper for elevation to the barley loft on the upper floor. After treatment from a large cleaning machine, the barley is distributed on the floors or taken to the steeps by a highly efficient system of band conveyors. The two steeps have an individual capacity of forty quarters. At the time of our visit the floor of the barley loft was covered with an immense consignment of the finest Scotch barley.

For drying the malt after it has germinated on the malting floor there are two kilns. One is floored with Hermann’s patent wire, the other with perforated iron plates, and both kilns are fitted with King’s patent regulators for controlling the furnaces. The fires are started with peat, coke being added after a period of twenty hours. Peat is used in a proportion of about two-thirds to one-third of coke. Longmorn is one of the large number of well-equipped distilleries that adhere to the old-fashioned two-roller mill, which in this case is said to be very satisfactory. The weighing machine has an admirable device for preventing dust, and for this reason the mill-room is unusually comfortable to work in. Hoppers with accommodation for 2,500 quarters are another notable feature of the maltings.

The mash-house is a fine large building with ample light and space. Attached to the mashtun are the customary appliances, including a copper spraying-rod for admitting the sparge water. For supplying hot water there are three immense coppers, all furnace-heated, which occupy a separate room adjoining the mashhouse. The quantity of malt mashed each week is 1,600 bushels, and the residue of draff is removed from the tun by a drag to the outside of the building, whence it is conveyed in trucks to principally Aberdeenshire and Banffshire. Power for all purposes comes from an excellent 25-h.p. oil engine, reinforced by a water wheel. In smart appearance, good lighting and ventilation Longmorn Distillery is second to none. The painted stairway in the mash-house, and the bright colours of the various vessels lend a cheerful tone to the whole place.

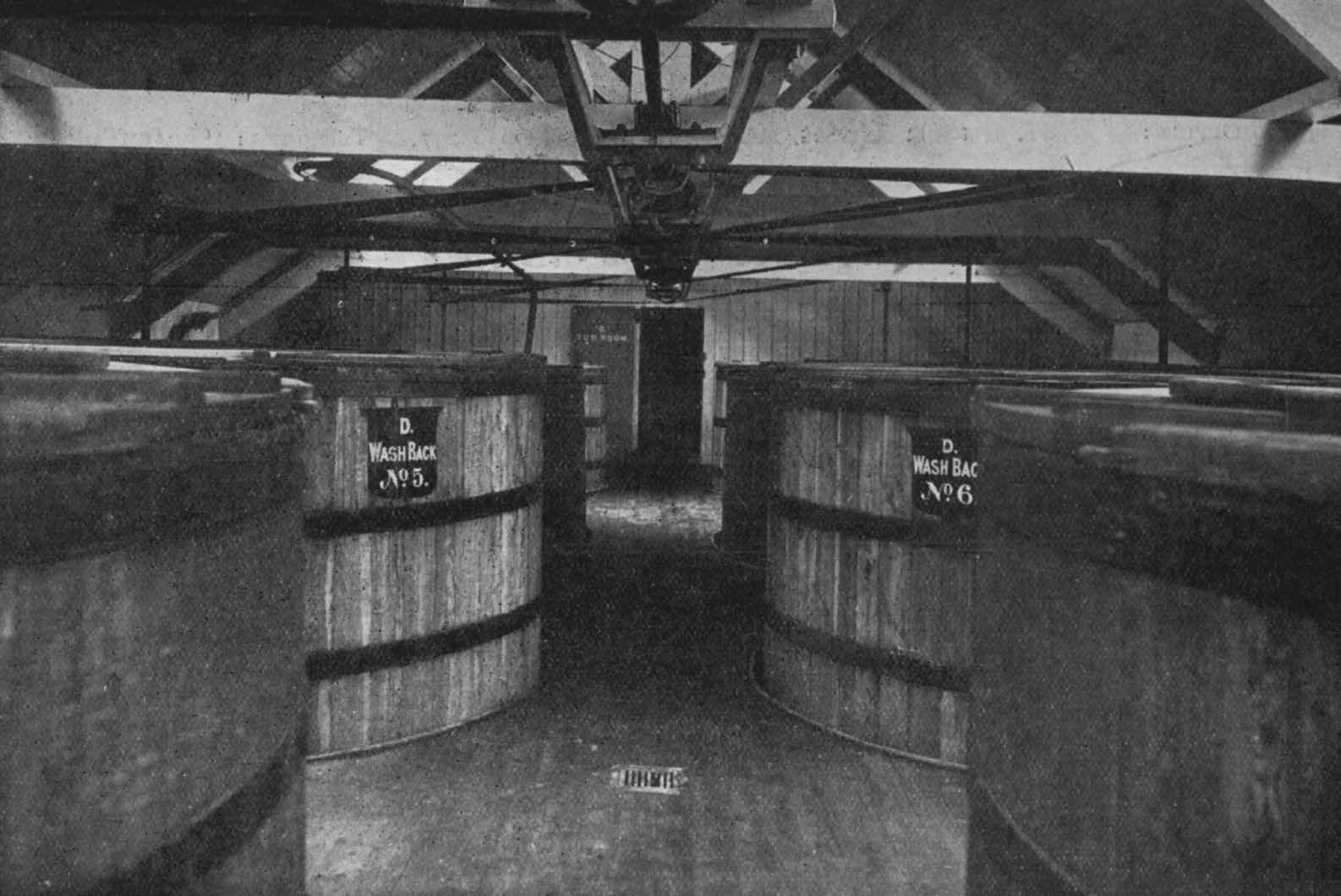

Passing up to the tun-room one noticed an auxiliary hot-water tank for cleansing purposes neatly installed above the wort-receiver and refrigerator. The tun-room itself, with part of the woodwork freshly painted in blue and white, is a large well-lit apartment containing eight washbacks and switchers.

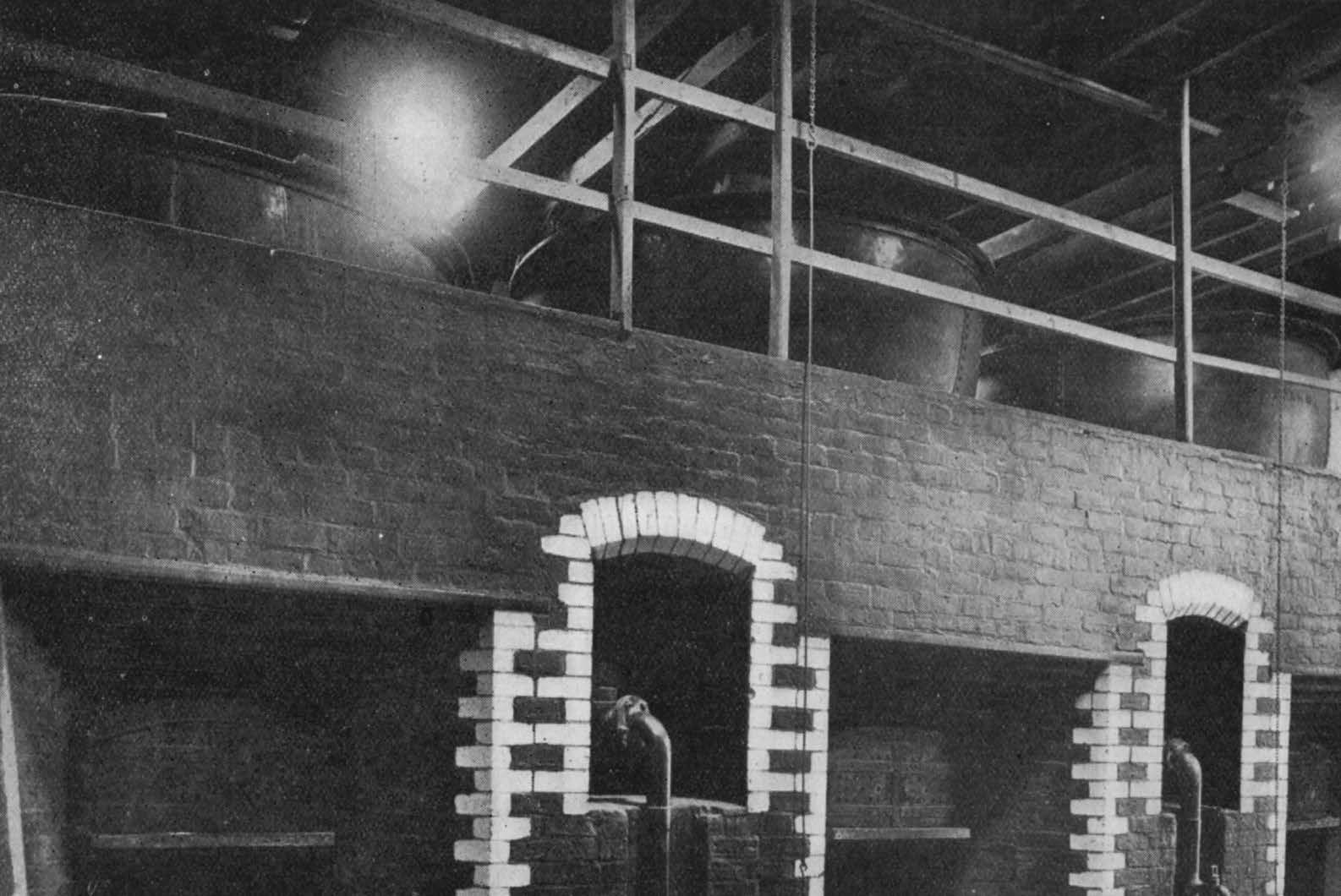

Longmorn is one of the few modern distilleries that can boast of four stills. These are placed side by side, two for wash, and the same number for Spirits. The wash-stills hold 2,207 gallons each, and the Spirit-stills have a capacity of 1,198 gallons and 2,000 gallons respectively. Worthy of special note is the receiver-room with woodwork handsomely painted in a colour scheme of red and blue and white walls. The Spirit-safe is one of the largest in Scotland, with four highly polished air valves. It may seem trivial to dwell upon the appearance of the works, but there can be no doubt that attention to this matter has a most beneficial effect upon the employees, and such instances prove that distilleries need not be as dull and dark as some unfortunately are.

The average weekly output of Longmorn-Glenlivet Whisky is 4,000 proof gallons, stored in a number of duty-free warehouses with accommodation for 800,000 gallons.

The method of disposing of the effluent from all sources is simple and efficient. Spent liquids are first run to a large cement cistern outside the premises, and subsequently pumped to an elevated tank placed near one of the entrances. From this vessel the effluent is run into two carts resembling those that are used to water the streets in towns, and finally sprayed over the neighbouring fields as manure. Some 27,000 gallons of the liquid are dispersed in this manner every week.

The principal agents for Longmorn-Glenlivet Whisky are Messrs. W. H. Nicolson and Company, of Edinburgh and London, and Messrs. Portal, Dingwall and Norris, Ltd., London.

Images © The British Library Board